A brief interview with Simone Giorgi, Sales Director at GNC Meccanica – a leading manufacturer of Suction Vacuum Cups for CNC machining centers.

We have selected questions among the most common ones that our customers ask us before making an online purchase in the store.

1. What is a vacuum clamping system for a CNC machine and when does a stoneworker need to use it?

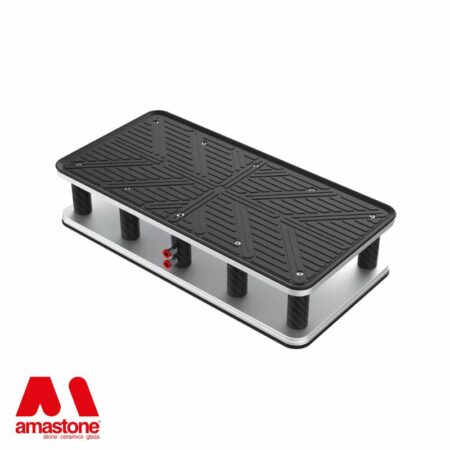

The vacuum clamping system is a system of cups (or pads) used every time you need to make a perimeter cut on a stone workpiece. This process would be impossible with traditional clamps.

2. Stoneworking is our main business, but are the suction cups used in other industries? Do cups change depending on the processed material? For example, are the suction cups that are installed in a machine for marble or granite the same as those that are installed in machines for glass or woodworking?

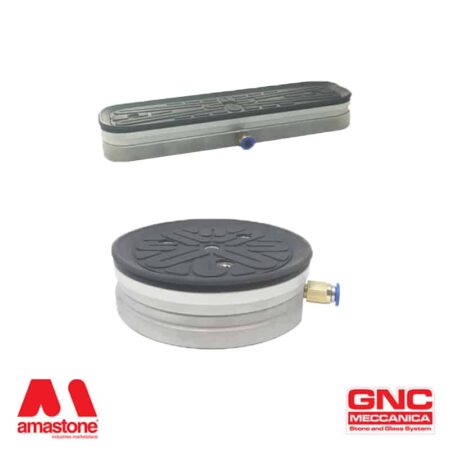

The suction cup systems find applications in many industries, from marble to glass, but also wood, metal, plastic and composite materials. The suction cups can change depending on the type of working surface. For example, if we want to work glass into a perfectly smooth surface, the suction cup would be equipped with a lip – ideal for having an effective and lasting solution. If we want to work marble or granite then it’s a little bit more complicated because the roughness and porosity of the materials can be completely different from one piece to another. In this case, the mousse EPDM gives

us the best performance, because it perfectly fits the surface of the marble/granite and mimics the asperity of the material.

3. What are the three main characteristics that a sucker must have in order to be used in a workshop for processing stone?

When we talk about stone, my advice is to use a suction cup with

mousse EPDM and for the double-vacuum suction cup, I recommend the rubber base that dramatically enhances the grip of the cup on the machine table. Finally, I would suggest using GNC Meccanica suction cups!

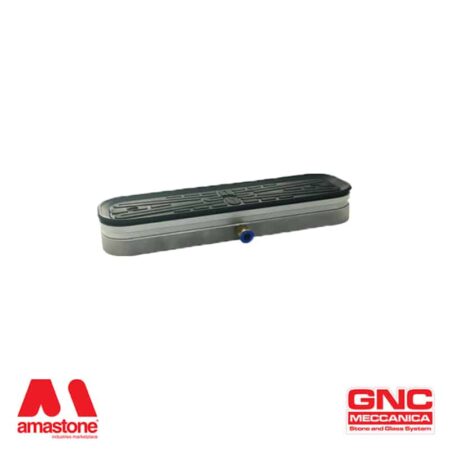

4. Do the suction cups need maintenance? What do you recommend for increasing their durability and efficiency?

I advise that you treat a suction cup as an essential part of your CNC working center, so I suggest washing them after every use, and disconnecting and storing them neatly away from the machine. Too often I see machine

tables with pads connected but unused, gathering dirt and water. Sometimes these have crushed seals that struggle to seal the vacuum when in use.

5. Which Italian manufacturers use the GNC Meccanica vacuum cups? Can you name some of them?

The Italian machine manufacturers who use GNC Meccanica products are Denver, CMS Brembana, Breton, Donatoni, Marchetti, Prussiani, GMM, Cobalm, Pavoni Automazioni, Emmedue, to name some of the biggest companies.

6. If I have special needs for my CNC machine, can you produce customized pads?

Absolutely, yes. Our policy is to be side by side with those who work every day on the CNC machine, so we are always available to meet customers’ special technical requirements.

7. If we need to change the type of seal – the EPDM lip, for example – would we be forced to change the cups?

NO, GNC is indeed the FIRST AND ONLY COMPANY IN THE WORLD to have created a suction cup that allows you to use the mousse or EPDM lip simply by removing one and putting on another. This is because our seals are designed to work without being glued to the suction plane (in EPDM foam glue we paste the ends of the seal, forming a ring, to avoid any kind of loss) and because, as said many times, we make it possible to change a single seal without changing the pad – unlike the competition.

8. Which vacuum system should be used with your cups?

The choice is between two systems: a vacuum generator, commonly called “Venturi System” that is economical and functional when using few sucker cups. The Venturi System requires maintenance and could be very noisy because of the constant loss of compressed air required to generate the vacuum inside the cone.

The second option, the most effective and common in my opinion, is

the Vacuum Pump, that is categorized by flow capacity (m3 / h) and which generally is already installed in machines that require suction cups. In this case, the number of pads that can be connected rises greatly, and maintenance, in this case, is simpler and does not require daily monitoring. That is why they often strongly recommend this option.

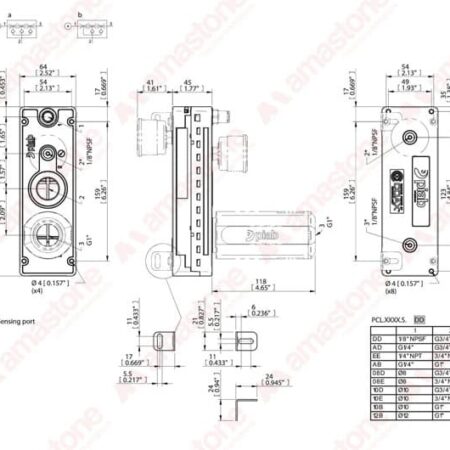

9. Does GNC Meccanica produce other products besides vacuum pads? Can you tell us which ones? For example, do I need a vacuum pump?

GNC Meccanica also produces lifting cups, manual and pneumatic clamps, workpiece reference stops and gripper tools – all of which are 100% made in Italy. The process starts from a solid block that is machined by numerical control machines and assembled by hand with a stainless steel plate cut by laser to improve stability without losing the elasticity of the plastic material. As for the vacuum systems, we always assemble complete systems: pump, pool, pipes and obviously vacuum cups and so on. You can ask us for a quote without any kind of commitment.

10. As the market leader for vacuum pads, tell me why I should choose GNC instead of one of your competitors?

Because GNC Meccanica provides 80% of the world’s leading manufacturers of CNC. GNC is a company that puts the customer first. We not only produce standard items, but we’re open to the development of customized solutions with reasonable prices. The shipping times are rapid, the product range is very wide, and thanks to the modular system, each component can be replaced without having to change the entire suction cup.

In addition, our vulcanized plans are GUARANTEED FOR LIFE. The production takes place entirely in Italy with great attention to quality – and also design – a particular feature of products Made

Diamond Blades

Diamond Blades Angle Grinder Tools

Angle Grinder Tools Polishing Machine Tools for Stone, Marble and Granite

Polishing Machine Tools for Stone, Marble and Granite Texture tooling

Texture tooling Adhesives and glue

Adhesives and glue Ceramic, Granite and Marble Drill Bits

Ceramic, Granite and Marble Drill Bits Sculpture – Stone carving tools

Sculpture – Stone carving tools Diamond Wires for Granite and Marble Quarries

Diamond Wires for Granite and Marble Quarries Cemetery and Graveyard Accessories

Cemetery and Graveyard Accessories CNC Vacuum Pods

CNC Vacuum Pods CNC Tool Holders

CNC Tool Holders CNC Tool Forks

CNC Tool Forks Positioning Alignment Lasers

Positioning Alignment Lasers Material Handling

Material Handling Machinery

Machinery Spare parts

Spare parts Electrical Spare Parts

Electrical Spare Parts Personal Protective Equipment

Personal Protective Equipment