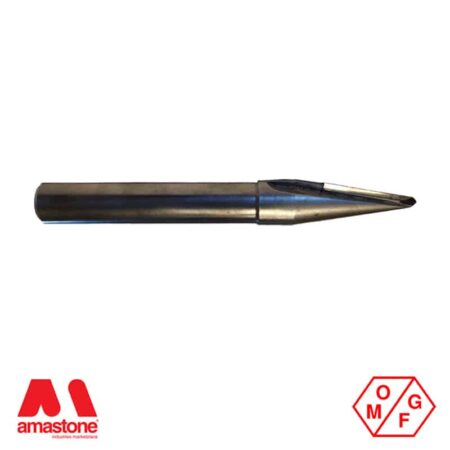

Electroplated carving tool for marble – OMGF

The difference between these electroplated diamond carving tools and a carbide bit is their superior feed rate, which comes at the expense of a rougher cut. To solve this problem of less clean-cut. They have an angle of 90 degrees, 105 degrees or 120 degrees, and they are used for carving and roughing on marble.

They have a cylindrical shank of 10 mm and they are holed to allow the flow of the water inside the tools.

Marble carving tools models

- electroplated engraving tool 90° – this tool has a tip of 90 degrees – holed

- electroplated engraving tool 105° – this tool has a tip of 105 degrees – holed

- electroplated engraving tool 120° – this tool has a tip of 120 degrees – holed

They can be used also to make writings and engravings because an electroplated carving tool is very fast (feed rate 100/150 mm per minute) but they leave a rough cut. For example, letter grooves on marble made by a widia tool are cleaner than the ones made by an electroplated carving tool. (Go to Widia 60° engraving tool)

Working parameters

When making carvings on marble by your CNC machine router it is recommended to proceed as follows:

- 3000/5000 rpm

- Feed rate 100/150 mm per minute.

- Maximum cutting depth per pass: 2/3 mm

- We recommend a ramp input

Diamond Blades

Diamond Blades Angle Grinder Tools

Angle Grinder Tools Polishing Machine Tools for Stone, Marble and Granite

Polishing Machine Tools for Stone, Marble and Granite Texture tooling

Texture tooling Adhesives and glue

Adhesives and glue Ceramic, Granite and Marble Drill Bits

Ceramic, Granite and Marble Drill Bits Sculpture – Stone carving tools

Sculpture – Stone carving tools Diamond Wires for Granite and Marble Quarries

Diamond Wires for Granite and Marble Quarries Cemetery and Graveyard Accessories

Cemetery and Graveyard Accessories CNC Vacuum Pods

CNC Vacuum Pods CNC Tool Holders

CNC Tool Holders CNC Tool Forks

CNC Tool Forks Positioning Alignment Lasers

Positioning Alignment Lasers Material Handling

Material Handling Machinery

Machinery Spare parts

Spare parts Electrical Spare Parts

Electrical Spare Parts Personal Protective Equipment

Personal Protective Equipment

Reviews

There are no reviews yet.