La società MMG SERVICE SRL ha ricevuto nel corso del 2020 e 2021 gli aiuti di stato pubblicati sul RNA sezione Trasparenza.

Floor Polishing Tools

Showing all 39 results

Pad Holder adapter AS > Velcro – Klindex

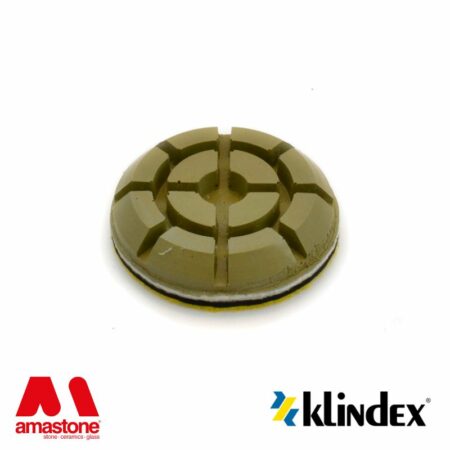

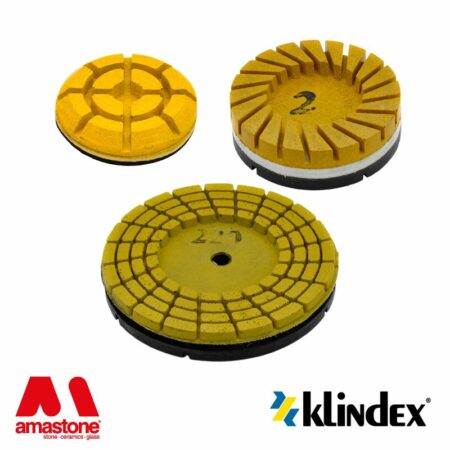

JUMPER CK ORANGE | Resin Bonded Abrasive Diamonds | Terrazzo – Klindex

READY COOL Tool holder plate for QUICK LOCK floor tools – Klindex

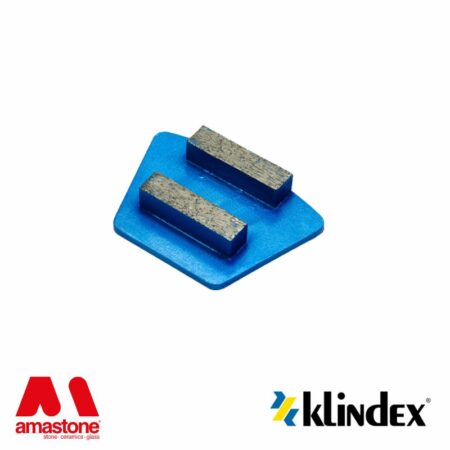

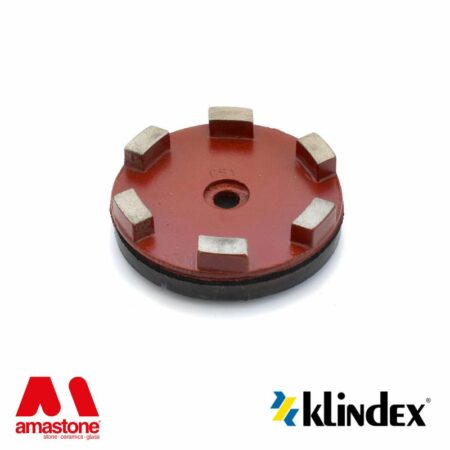

CD QUICK LOCK Diamond Segments for Floor Grinding | Hard Concrete – Klindex

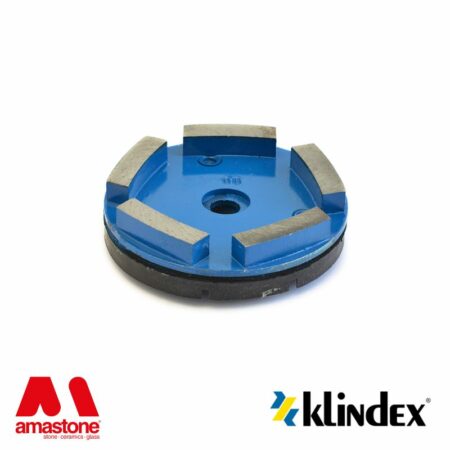

DA QUICK LOCK Diamond Segments for Floor Grinding | Concrete – Klindex

SUPERSHINE SOFT Diamond Polishing Pads for Floor Polishers – Klindex

WATERFIRE Hand Floor Grinder and Polisher – Klindex

UFO Portable Grinding Planetary Machine – Klindex

FLASH DIAMOND 3-Step Floor Polishing Abrasives – Klindex

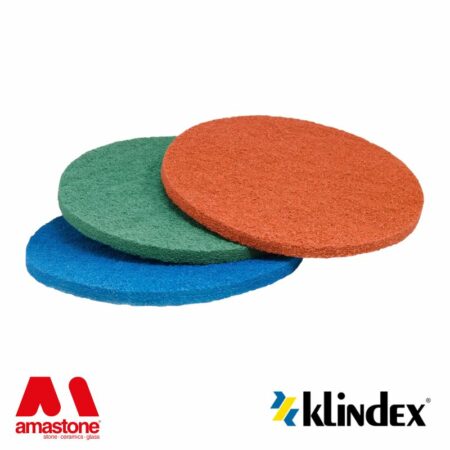

TRIPAD 3-step Diamond Pads for Floor Cleaning Machines – Klindex

POLISH KMT | Polishing Powder for Carrara and Soft Marble – Klindex

POLISH KP85 | Polishing Powder for Marble – Klindex

POLISH KP92 | Polishing Powder Hard Marble and Limestone – Klindex

ELICA Diamond Floor Polishing Pads | Concrete/Marble – Klindex

Klindex Diamond Pads for Cleaning and Polishing Floor Machines

JUMPER GREEN Floor Polisher Resinoid Abrasives | Concrete – Klindex

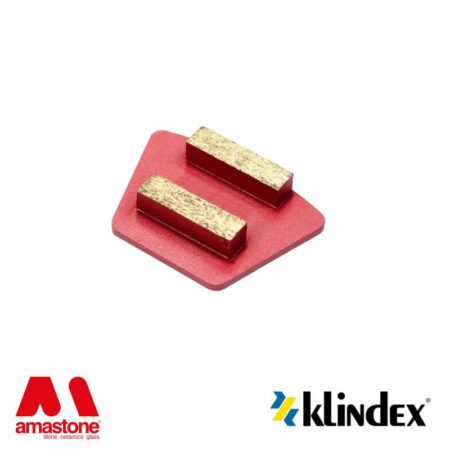

JUMPER GK RED | Resin Bonded Abrasive Diamonds | Granite – Klindex

JUMPER MK YELLOW | Resin Bonded Abrasive Diamonds | Marble – Klindex

UNIKA Professional Single-Disc Floor Polisher – Klindex

ROCKY Single-disc Floor Machine 1.1 kW – Klindex

Hercules 451 Floor Grinder with DCS System – Klindex

Levighetor 640 Professional TOP Floor Grinder – Klindex

Klindex GS Series Floor Grinding Wheels | Granite and Porcelain stoneware

Klindex MS Series Floor Grinding Wheels | marble

Klindex DA Series Floor Grinding Wheels | medium abrasive concrete

RXD Sorma diamond floor polishing pads

DIAFLOOR SPB Sorma diamond floor polishing pads

LINDA VELOCE Floor Cleaning Machine 1.9 kW Single speed – Battipav

MASTER LINDA floor cleaning machine – Battipav

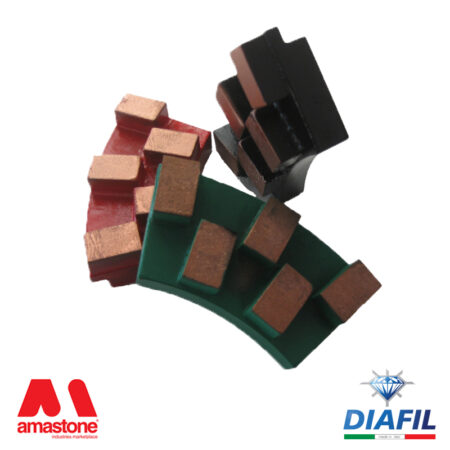

Munchen 3S MRB – Polishing diamond abrasive for floor sanders – Diafil

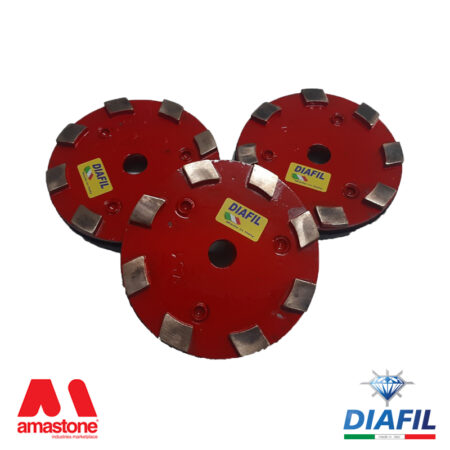

Metal Bond Floor Grinding abrasives – Metal Diamando MS -Diafil

Americano MRB Polishing diamond abrasive for floor sanders – Diafil

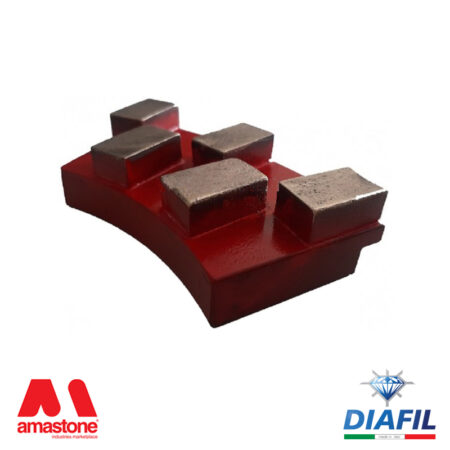

Cassani Metallic diamond grinding abrasives – Diafil

Floor Polisher Diamond Pads “Abralux” – Diafil

Floor Polishing Tools

Professional tools for floor polishing: polishing pads, pad holders, diamond tools, brushes, and more.

Floor Polishing Tools category, here you’ll discover a wide selection of professional equipment and accessories designed to help you achieve stunning, polished floors with ease.

Whether you’re a professional contractor or a DIY enthusiast, we’ve got you covered with a range of tools, machines, and products suitable for various flooring materials, including marble, granite, concrete, and more.

From powerful floor polishing machines to diamond polishing pads, our collection offers the perfect solutions for enhancing the beauty and durability of your floors. Transform dull and worn surfaces into brilliant, mirror-like finishes that will leave a lasting impression.

Explore our floor polishing tools and buffering tools; take the first step towards creating floors that shine with elegance and sophistication.

Buffing and polishing are two distinct processes used to enhance the appearance of floors, and they serve different purposes:

- Buffing a Floor:

- Purpose: Buffing is primarily done to maintain the existing shine and smoothness of a floor. It is a maintenance process used to remove minor scratches, scuff marks, and dullness that may have developed over time.

- Method: Buffing involves the use of a floor buffer or a burnishing machine equipped with a non-abrasive pad or a very fine abrasive pad. These machines rotate at high speeds, creating friction that helps to restore the glossiness of the floor.

- Products: Buffing typically uses a buffing compound, a polishing powder, or a high-gloss floor finish to achieve the desired shine.

- Frequency: Buffing is performed regularly to keep the floor looking its best, and it does not involve the removal of any material from the floor surface.

- Polishing a Floor:

- Purpose: Polishing, on the other hand, is a more intensive process used to enhance the shine and smoothness of a floor, often as part of initial floor finishing or restoration efforts. It can be used to remove deeper scratches and imperfections.

- Method: Polishing typically involves the use of specialized equipment such as floor polishing machines with diamond-impregnated abrasive pads. These machines are capable of removing a thin layer of the floor’s surface to reveal a new, shiny layer.

- Products: Polishing usually involves the use of diamond polishing pads or abrasive compounds that are progressively finer to achieve the desired level of shine and smoothness.

- Frequency: Polishing is less frequent than buffing and is typically done as a part of a floor maintenance or restoration project.

In summary, buffing is a less aggressive process aimed at maintaining and refreshing the shine of a floor’s surface, while polishing is a more intensive process that can remove deeper imperfections and create a high-gloss finish. The choice between buffing and polishing depends on the condition of the floor and the level of shine and smoothness desired.

If you are a stone fabricator with an in-line automatic polishing machine have a look at the: granite polishing tools

Diamond Blades

Diamond Blades Angle Grinder Tools

Angle Grinder Tools Polishing Machine Tools for Stone, Marble and Granite

Polishing Machine Tools for Stone, Marble and Granite Texture tooling

Texture tooling Adhesives and glue

Adhesives and glue Ceramic, Granite and Marble Drill Bits

Ceramic, Granite and Marble Drill Bits Sculpture – Stone carving tools

Sculpture – Stone carving tools Diamond Wires for Granite and Marble Quarries

Diamond Wires for Granite and Marble Quarries Cemetery and Graveyard Accessories

Cemetery and Graveyard Accessories CNC Vacuum Pods

CNC Vacuum Pods CNC Tool Holders

CNC Tool Holders CNC Tool Forks

CNC Tool Forks Positioning Alignment Lasers

Positioning Alignment Lasers Material Handling

Material Handling Machinery

Machinery Spare parts

Spare parts Electrical Spare Parts

Electrical Spare Parts Personal Protective Equipment

Personal Protective Equipment