La società MMG SERVICE SRL ha ricevuto nel corso del 2020 e 2021 gli aiuti di stato pubblicati sul RNA sezione Trasparenza.

CNC Conical Carving Tools

CNC Conical Carving Tools for Marble and Granite

Showing all 16 results

CNC 45° Vacuum-brazed Conical Finger Bit – Amastone

CNC electroplated marble carving conic router bits

Electroplated conic carving router bit – shank 10 mm – Marble

Electroplated conic carving router bit – Marble – Diamar

Carving router bit – Amastone

45° router bit for marble and ceramic

45° Router Bit for Quartz and Granite

Carbide conic carving router bit – Marble

Carving router bit h170 mm – Marble

Carving router bit h110 mm – Marble

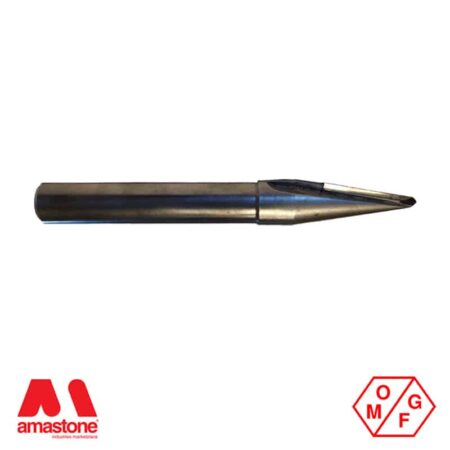

Spiral engraving router bit – Marble – OMGF

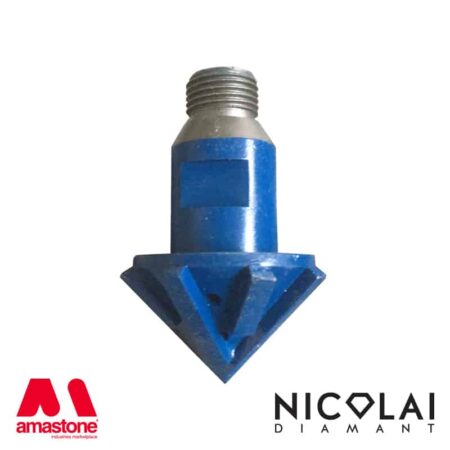

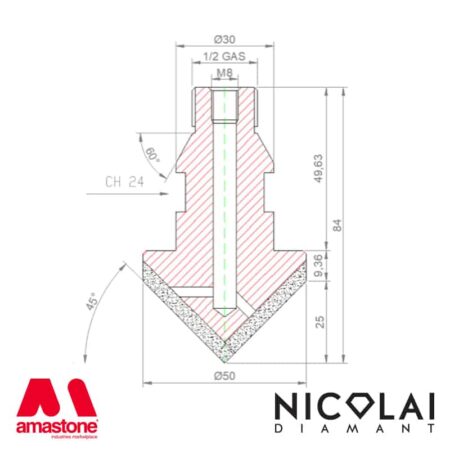

Conical router bit for Granite – Nicolai

Electroplated diamond carving tool for ceramic and granite – Diamar

Electroplated diamond carving tool for marble – OMGF

Polycrystalline carving router bit – Granite – OMGF

Engraving router bit – 14 mm cylindrical shank – Marble – OMGF

CNC Conical Stone carving and working tools

CNC Tools for rough-cutting stone bas-reliefs

Carbide, diamond electroplated, rounded, and ball-noded bits for CNC machines to work marble, granite, and ceramic

These tools are designed for bas-relief roughing and material removal.

What is Roughing in Stone Machining?

Roughing operation in machining is used to remove bulk material rapidly and roughly shape the workpiece to the desired form, in order to make the subsequent processing (that we call Finishing) faster, more convenient, and efficient

We offer bits having various cutting angles, radii, and, cutting edges up to 120 mm (ball nose-round).

Most of our bits have a 1/2 gas connection, others have a 14-mm cylindrical connection.

We offer bits with cutting angles of 20°. These are very precise bits able to operate in the most hard-to-reach areas of a bas-relief.

Note:

Carbide and electroplated bits are used to work marble and limestone;

Polycrystalline and sintered tools are recommended for harder materials such as granite, lava stone, and engineered stone.

Each product page provides the working parameters for granite and marble tools. These are generic parameters referring to the use of a bit on a solidly based machine with insignificant vibration.

Generally speaking, the parameters can be changed in accordance with the following rule: “the shorter the cutting depth per pass, the greater the feed rate at which the bit can work”

For example:

- with a cutting depth of 4-5 mm per pass, the feed rate is 100 mm/min

- with a cutting depth of 1 mm per pass, the feed rate is 500 mm/min

Note: if we increase the feed rate, the bit’s speed of rotation must also be increased.

As regards the plunge rate into the material, we recommend a rate no greater than 100–120mm/min with ramp purge motions that do not exceed 10 – 20° with respect to the material surface.

Always use enough water to cool the bit.

Almost all the bits come with a bored through-tool version allowing water to pass through the bit, cooling it more effectively, and removing undesired cutting debris.

CNC Stone router bits may be used for roughing and finishing stone with a CNC stone router.

Note: For the hand stone carving tools visit the category: STONE CARVING TOOLS

These bits have diverse names and are also known as CNC milling bits, CNC Stone carving bits, Granite CNC Router Bits, Marble CNC Router Bits, Stone CNC Router Bits, and Quartz Router bits.

Also, due to their complementary usage, you might find what you are looking for among our engraving tools.

Related CNC Stone Tools categories:

- CNC Finger Bits (cutting, profiling, milling, sink cut-out)

- CNC Drill Bits (drilling)

- CNC Stone Engraving Bits (engraving, writing, finishing, and super-finishing)

- CNC Stubbing Wheels (material removal, recessing, and pocketing)

- CNC Profiling and Profile Wheels (edge profiling and polishing)

- CNC Drain Board Tools (grooving)

- CNC Machine blades

- Polycrystalline bits

- CNC Replacement Head Bits

- CNC Tool holders

For a full list of the best CNC Tools for Professionals, start over from our homepage.

Diamond Blades

Diamond Blades Angle Grinder Tools

Angle Grinder Tools Polishing Machine Tools for Stone, Marble and Granite

Polishing Machine Tools for Stone, Marble and Granite Texture tooling

Texture tooling Adhesives and glue

Adhesives and glue Ceramic, Granite and Marble Drill Bits

Ceramic, Granite and Marble Drill Bits Sculpture – Stone carving tools

Sculpture – Stone carving tools Diamond Wires for Granite and Marble Quarries

Diamond Wires for Granite and Marble Quarries Cemetery and Graveyard Accessories

Cemetery and Graveyard Accessories CNC Vacuum Pods

CNC Vacuum Pods CNC Tool Holders

CNC Tool Holders CNC Tool Forks

CNC Tool Forks Positioning Alignment Lasers

Positioning Alignment Lasers Material Handling

Material Handling Machinery

Machinery Spare parts

Spare parts Electrical Spare Parts

Electrical Spare Parts Personal Protective Equipment

Personal Protective Equipment