La società MMG SERVICE SRL ha ricevuto nel corso del 2020 e 2021 gli aiuti di stato pubblicati sul RNA sezione Trasparenza.

Ceramic Cutting Blades

Showing all 19 results

ZENITH Porcelain and Dekton Bridge Saw Blades – Amastone

GALAXY Diamond Blade for large ceramic slabs – Diatex

Perfetto CPF Diamond blade for wet saw – Montolit

DNA CX Tile Saw Continuous Rim Blade – Montolit

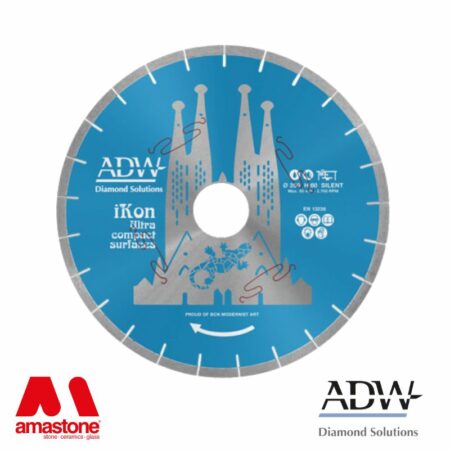

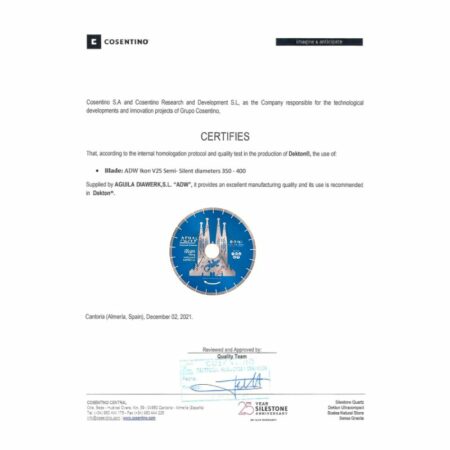

ADW iKon Ceramic Ultra Compact Surface Bridge Saw Blade

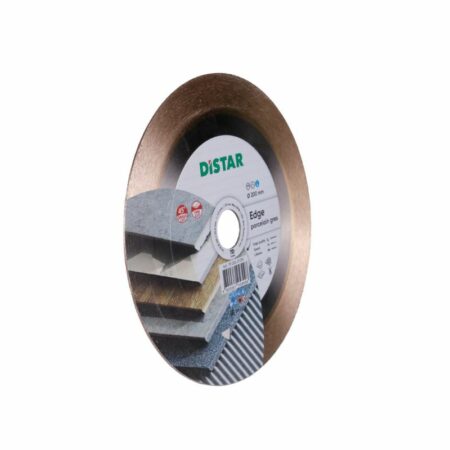

1A1R EDGE Blade for ceramic miter cuts on table saws – Distar

Montolit XAMURAY Continuous rim diamond tile blade

Montolit DNA Sector SCX Blade for Wet Saw – Montolit

Ceramic blade for saws with no-variable speed “LP40F” – Diatex

STONEGLASS bridge saw blades LK39E – Diatex

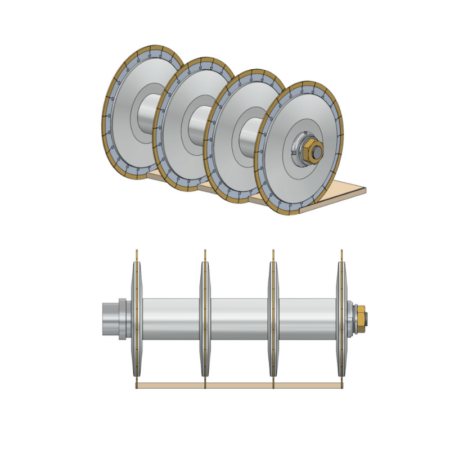

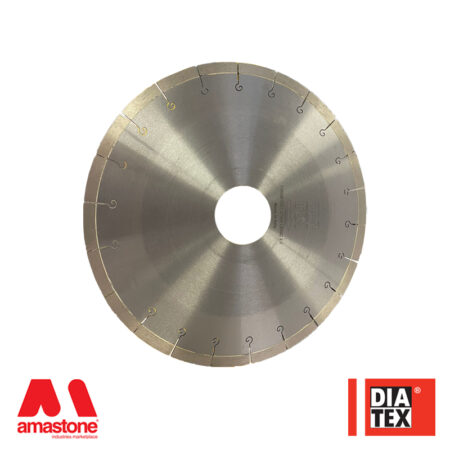

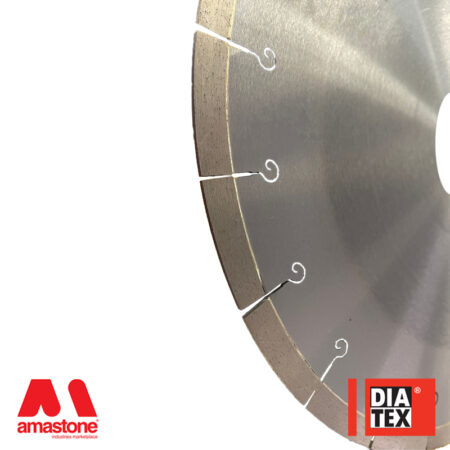

Multi-blade ceramic cutting machine blades – Diatex

High-speed reinforced ceramic cutting blade “Faster PRO” Ø400 – Diatex

Diatex Tile-Saw Ceramic Blades

High-speed ceramic cutting blade “Faster” – Diatex

Sharpening bar for blades

Diatex FORTYFIVE” 45° silent-core bridge saw blades for Laminam or Neolith

Diatex “MITERcut” 45° bridge saw blade for ceramics

Lapitec bridge saw blades “LAPIcut” – Diatex

“GREScut” Ceramic Cutting bridge saw blades for Laminam, Neolith, and Porcelain – Diatex

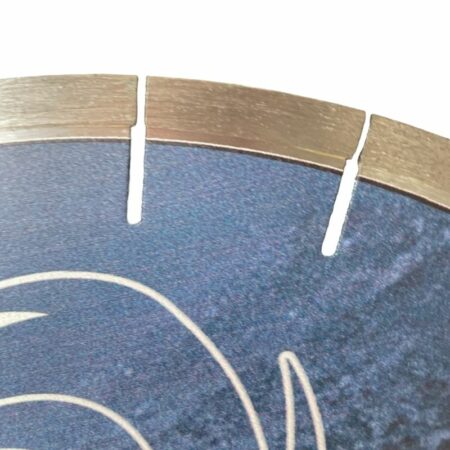

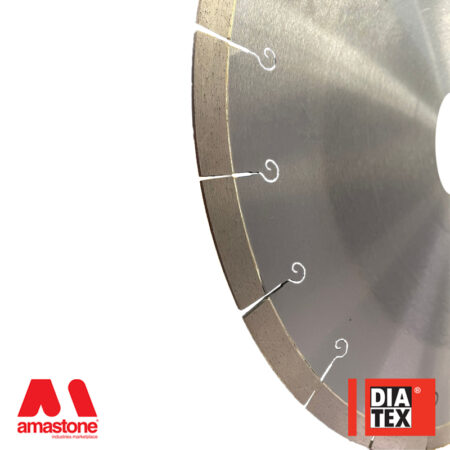

Diamond Bridge Saw blades for cutting Ceramic, Porcelain, Sintered and Ultra-compact surfaces

High-quality diamond blades for cutting ceramic slabs and large-format tiles and pieces.

We offer made-in-Italy Diatex Blades designed for cutting ceramic slabs, porcelain, and ultra-compact surfaces.

While quartz (blades for quartz) remains the most popular hard surface for kitchens, porcelains have been gaining market share, especially as an increasing number of fabricators are successfully getting to grips with processing the large format slabs used for kitchen worktops.

Porcelain surfaces are sometimes described as ceramic, sintered, compact or ultra-compact materials. They blend ceramic clays, mineral colorings and natural materials by compressing them,(sintering and thats because sintered materials) and then firing them.

Laminam (porcelain), Dekton, Lapitec, Neolith, and similar ceramic-based slabs (Large ceramic slabs) are made in sizes larger than 3 meters, and thanks to their considerable wear resistance, they are now the most upscale material for making kitchen tops and fronts. They are gaining in popularity as solid surfaces, facades, siding, and flooring, but are notoriously difficult to cut.

The production process used to manufacture these materials is known as sintering, a special procedure that transforms the raw materials on a molecular level. Sintering consists of heat-treating pulverized mixtures of inert materials compacted at high pressure. It causes the powder granules to fuse together, thus eliminating porosity and increasing the density of the components, creating a highly resistant material.

Choose the right blade, for quicker, cheaper, and more precise cutting.

For more information about ceramic blades or to place an offline order don’t hesitate to contact us at

Diamond Blades

Diamond Blades Angle Grinder Tools

Angle Grinder Tools Polishing Machine Tools for Stone, Marble and Granite

Polishing Machine Tools for Stone, Marble and Granite Texture tooling

Texture tooling Adhesives and glue

Adhesives and glue Ceramic, Granite and Marble Drill Bits

Ceramic, Granite and Marble Drill Bits Sculpture – Stone carving tools

Sculpture – Stone carving tools Diamond Wires for Granite and Marble Quarries

Diamond Wires for Granite and Marble Quarries Cemetery and Graveyard Accessories

Cemetery and Graveyard Accessories CNC Vacuum Pods

CNC Vacuum Pods CNC Tool Holders

CNC Tool Holders CNC Tool Forks

CNC Tool Forks Positioning Alignment Lasers

Positioning Alignment Lasers Material Handling

Material Handling Machinery

Machinery Spare parts

Spare parts Electrical Spare Parts

Electrical Spare Parts Personal Protective Equipment

Personal Protective Equipment