ZENITH Bridge saw Diamond Blade for Porcelain and Dekton slabs – Amastone

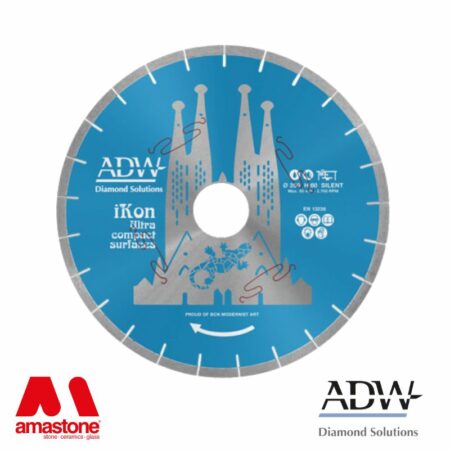

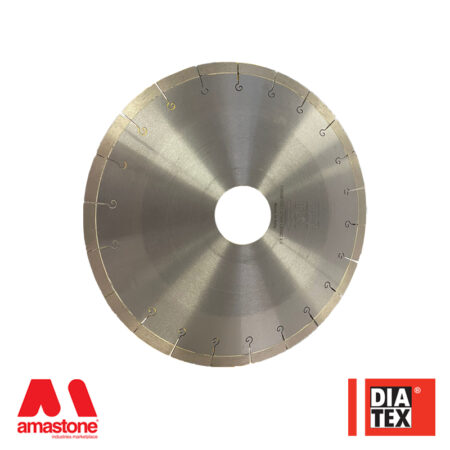

The new ZENITH diamond blade for cutting large porcelain stoneware ceramic (UCS) slabs with bridge saws.

Cutting porcelain ceramic is no longer a problem!

Whether you have an advanced bridge saw with variable-speed disc rotation or a fixed-speed machine, with our ZENITH blade, you won’t encounter cutting issues anymore.

3 advancements in a single blade by Amastone:

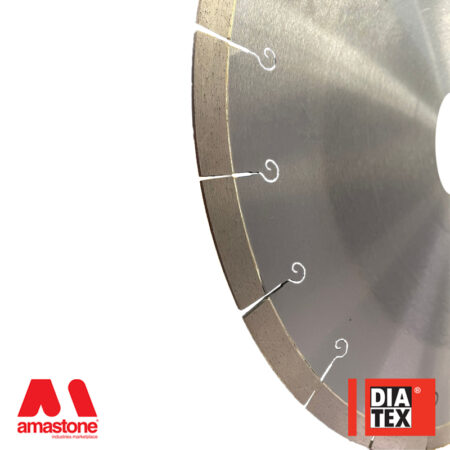

- A new diamond sector with specific grain for cutting porcelain

- A new super-thin shape of the sector

- Specially reinforced core allowing clean, fast cuts with very low disc closure probability.

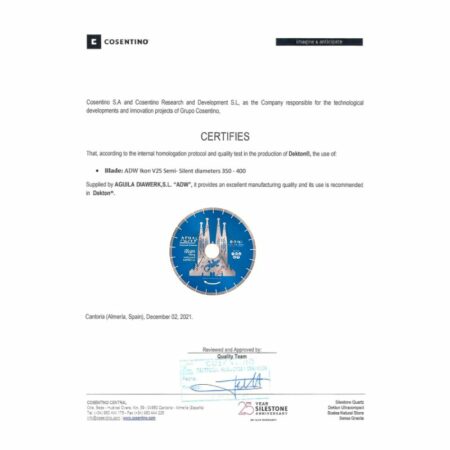

ZENITH allows working on all new ceramic materials, from all brands including Lapitec@, Dekton@, Laminan@, Neolith@, etc., both with bridge saws with speed adjustments and with traditional fixed-speed saws (without an inverter on the disc motor).

Often, discs suffer from loss of sharpness during their lifespan; when the disc closes, it means the diamond sector has lost its cutting capacity, thus forcing the cut and causing slab breakage. ZENITH with its new sector has an extremely low percentage of sharpness loss; it rarely closes. Causes may include usage on non-ceramic materials, usage of little water, and other factors. This means it rarely needs sharpening. Thanks to its reinforced core, the Zenith blade allows high cutting speeds on modern machines with inverters and provides excellent finishing even at 45° cuts. ZENITH is a diamond blade suitable for both straight and inclined cuts.

Many companies hesitate to innovate their products for fear of damaging sales of already established ones. However, at Amastone, we believe that the constant development of new solutions, more performant and even more cost-effective than previous ones, is essential for ensuring lasting success. We invite you to try our ZENITH blade: It won’t disappoint you.

Usage Parameters for Machines with Inverters

| Slab Thickness | Blade Rotation Speed (RPM) | Straight Cutting Speed (m/min) | 45° Cutting Speed (m/min) |

|---|---|---|---|

| 6-9 mm | 2300-2500 (Ø350), 2000-2200 (Ø400) | 2.5 – 4 | 1.3 – 2 |

| 10-12 mm | 2300-2500 (Ø350), 2000-2200 (Ø400) | 2 – 3.5 | 1 – 1.5 |

| 13-20 mm | 2300-2500 (Ø350), 2000-2200 (Ø400) | 1.8 – 2.5 | 0.7 – 1 |

| 13-20 mm (DEKTON + LAPITEC) | 2300-2500 (Ø350), 2000-2200 (Ø400) | 1.5 – 2 | 0.7 – 1 |

Usage Parameters for Machines without Inverters

| Slab Thickness | Blade Rotation Speed (RPM) | Straight Cutting Speed (m/min) | 45° Cutting Speed (m/min) |

|---|---|---|---|

| 6-9 mm | 1700-2000 | 2 – 3 | 1 – 1.5 |

| 10-12 mm | 1700-2000 | 1.5 – 2.5 | 0.7 – 1.2 |

| 13-20 mm | 1700-2000 | 1.2 – 1.6 | 0.5 – 0.7 |

| 13-20 mm (DEKTON + LAPITEC) | 1700-2000 | 1 – 1.4 | 0.5 – 0.7 |

Diamond Blades

Diamond Blades Angle Grinder Tools

Angle Grinder Tools Polishing Machine Tools for Stone, Marble and Granite

Polishing Machine Tools for Stone, Marble and Granite Texture tooling

Texture tooling Adhesives and glue

Adhesives and glue Ceramic, Granite and Marble Drill Bits

Ceramic, Granite and Marble Drill Bits Sculpture – Stone carving tools

Sculpture – Stone carving tools Diamond Wires for Granite and Marble Quarries

Diamond Wires for Granite and Marble Quarries Cemetery and Graveyard Accessories

Cemetery and Graveyard Accessories CNC Vacuum Pods

CNC Vacuum Pods CNC Tool Holders

CNC Tool Holders CNC Tool Forks

CNC Tool Forks Positioning Alignment Lasers

Positioning Alignment Lasers Material Handling

Material Handling Machinery

Machinery Spare parts

Spare parts Electrical Spare Parts

Electrical Spare Parts Personal Protective Equipment

Personal Protective Equipment

Reviews

There are no reviews yet.