La società MMG SERVICE SRL ha ricevuto nel corso del 2020 e 2021 gli aiuti di stato pubblicati sul RNA sezione Trasparenza.

CNC Tool holders

Selecting the Right CNC Tool Holder for Enhanced Machine Performance

CNC Tool Holders

If your machine incorporates an automatic tool changer or quick-release spindle, you are certain to be familiar with tapered tool holders.

CNC Tool holders must be perfectly balanced for safe operation and to achieve first-rate results with zero defects

The tool holder for your application depends on the spindle unit, the CNC machine model, the brand, and maybe even the tool fork.

So how do I choose the right tool holder for CNC machines?

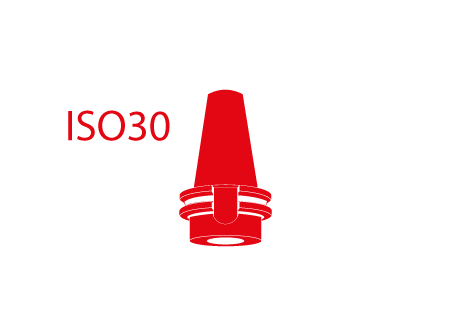

First of all, identify the tool holder standard you need. We offer a wide variety of tapered tool holders meeting various standards such as:

- ISO (ISO30, ISO40 ISO50)

- BT (BT30, BT40, BT50);

- HSK

Next, chose the brand of your machine since the tool holder you will need is a function of the CNC machine model and brand.

After that, choose the appropriate connection mechanism of the tool itself. In the stone industry, you are likely to encounter

- Cylindrical shank tools that use a tapered ER collet chuck

- Tools with half gas fittings such as the 1/2 Gas drill point tool holder taper

- Stubbing wheels that require a flanged fitting)

- Profile wheels with a special tool holder for grinding wheel

As regards material type, our tool holders come with three different material treatments:

- Stainless Steel Endurance treatment provides premium quality, a smooth surface, with a low risk of breakage (translating into safety for operators and augmented protection against water and dust)

- Darkside heat treatment at a convenient price, requiring little-to-no maintenance, passing the 400-hr salt spray corrosion test with an HRC hardness of 60 in the diffusion zone and 35 in the core. Completely rustproof with no chipping or flaking)

- Nickel-plated (with a Nickel layer providing corrosion and wear resistance)

Fine-balanced CNC Toolholders are essential to securely fasten your cutting tools to your machine spindle, especially when working with hard materials such as marble or granite.

Choosing the right holder is absolutely essential for superior tool performance, long tool life, and most importantly of all, precision work.

Our CNC tool holders are made in Italy by IMS, the stone and glass industry’s leading tool holder manufacturer. Most likely, your current stone or glass CNC machine already uses IMS tool holders.

We also sell ER collets, collet nuts, pull studs (retention knobs), and even spanner wrenches.

Check also our Tool holder accessories and other accessories are available in our CNC Machine Accessories section.

If you need help selecting the right tool holder for your needs, send us a photo of your current tool holder, collet nut, or pull studs (retention knob) along with the spindle plate, and your machine brand to . We will get back to you right away!

Diamond Blades

Diamond Blades Angle Grinder Tools

Angle Grinder Tools Polishing Machine Tools for Stone, Marble and Granite

Polishing Machine Tools for Stone, Marble and Granite Texture tooling

Texture tooling Adhesives and glue

Adhesives and glue Ceramic, Granite and Marble Drill Bits

Ceramic, Granite and Marble Drill Bits Sculpture – Stone carving tools

Sculpture – Stone carving tools Diamond Wires for Granite and Marble Quarries

Diamond Wires for Granite and Marble Quarries Cemetery and Graveyard Accessories

Cemetery and Graveyard Accessories CNC Vacuum Pods

CNC Vacuum Pods CNC Tool Holders

CNC Tool Holders CNC Tool Forks

CNC Tool Forks Positioning Alignment Lasers

Positioning Alignment Lasers Material Handling

Material Handling Machinery

Machinery Spare parts

Spare parts Electrical Spare Parts

Electrical Spare Parts Personal Protective Equipment

Personal Protective Equipment