I broke my CNC router bit – How did that happen?

A customer of mine called yesterday stating that the CNC Router bit he uses regularly just broke.

Why? It could be due to a manufacturing defect, but that is not very likely.

I then asked him to explain what work he was doing with his CNC machine when the breakage occurred.

He was working on granite making just 1-millimeter deep cuts into the stone (in fact this customer usually goes much deeper, cutting 4 or 5 mm deep each pass!)

Then I asked him how he had inserted the bit into the ER collet.

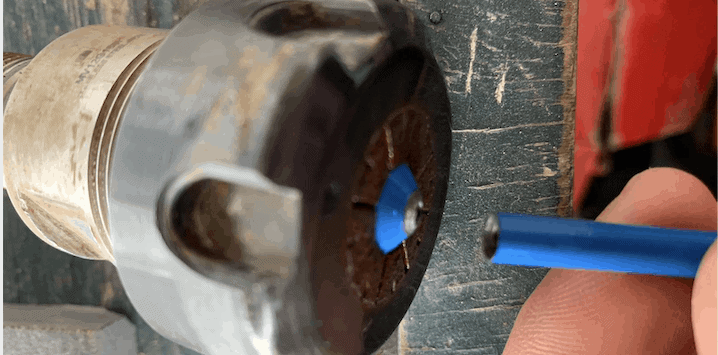

At this point, I had him send me a photo of the collet as it was used.

This is the actual scenario:

- He was working on a very hard material;

- He was working with a 9-cm long granite bit inserted just a few centimeters into the ER collet;

- The ER collet he was using was very rusty and worn;

- He had set a cutting depth of 1 mm for each pass;

The bit didn’t break because of a manufacturing defect but due to vibrations. With a rotational speed of 8000 rpm, the excessive vibrations ended up breaking the bit in the shank even though it appeared to be working well and was not making any unusual noise.

The bit vibrations (as often happens) had more than one cause.

- The bit had not been inserted as far as it could go into the collet and was therefore very long.

- The collet did not form a stong grip being that it was already rusted and worn. Thus the grip was poor and caused the bit to rest crookedly in the collet.

- The cutting depth was too short and failed ot exploit the material’s capacity to dampen vibrations. In this case, making shallow cuts was not a benefit, but a problem for the router bit.

To use the bits as best as possible, prevent premature wear and breakage, to the extent possible, vibrations must be minimized.

- Make sure that the ER collet is in good condition and not overly worn.

- Work with a router bit as short as possible to minimize leverage acting on it while cutting. The bit is inserted into the ER collet to a greater or less depth depending on the work you are doing (sett the photo below)

- When cutting very hard materials, such as granite or marble, make sure you make deeper passes to the vibration-damping effect of the material itself.

Reduce the feed by half and double the cutting depth of each pass.

In this way you can reduce the vibrations and the probability of your router bit breaking.

Diamond Blades

Diamond Blades Angle Grinder Tools

Angle Grinder Tools Polishing Machine Tools for Stone, Marble and Granite

Polishing Machine Tools for Stone, Marble and Granite Texture tooling

Texture tooling Adhesives and glue

Adhesives and glue Ceramic, Granite and Marble Drill Bits

Ceramic, Granite and Marble Drill Bits Sculpture – Stone carving tools

Sculpture – Stone carving tools Diamond Wires for Granite and Marble Quarries

Diamond Wires for Granite and Marble Quarries Cemetery and Graveyard Accessories

Cemetery and Graveyard Accessories CNC Vacuum Pods

CNC Vacuum Pods CNC Tool Holders

CNC Tool Holders CNC Tool Forks

CNC Tool Forks Positioning Alignment Lasers

Positioning Alignment Lasers Material Handling

Material Handling Machinery

Machinery Spare parts

Spare parts Electrical Spare Parts

Electrical Spare Parts Personal Protective Equipment

Personal Protective Equipment