In the CNC processing industry, precision is key. Understanding the direction of threads on your tools and adapters is crucial.

This guide will provide you with a comprehensive understanding of how to identify thread direction, ensuring you can work effectively and safely.

What is Thread Direction?

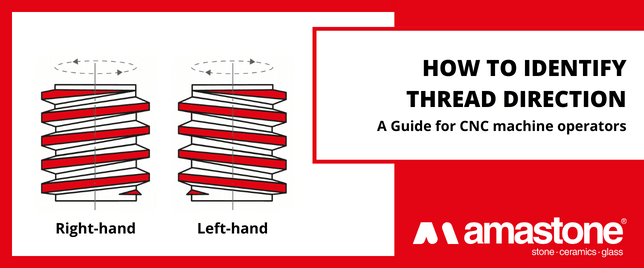

Thread direction refers to the orientation of the thread helix as it wraps around the cylindrical body of a screw, bolt, or nut. There are two main types of thread direction: left-hand (LH) and right-hand (RH).

Right-Hand Threads (RH)

Right-hand threads are the most common type of threads in tools for CNC machines. If you hold a right-hand threaded bolt or screw in your hand and turn it in a clockwise direction (the same direction that the hands of a clock move), it will move away from you. This is often remembered as “righty-tighty,” as turning the screw to the right (clockwise) tightens it.

Left-Hand Threads (LH)

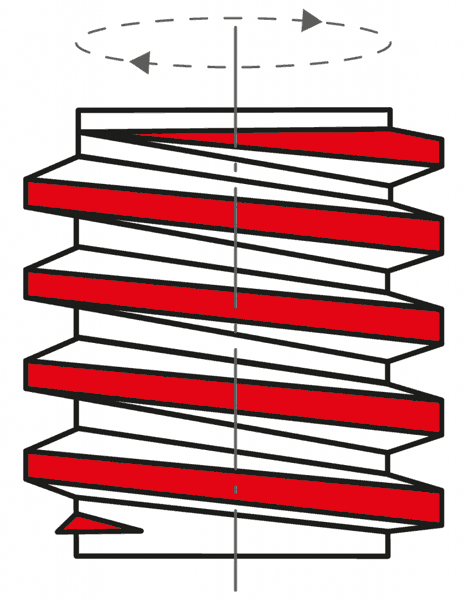

Left-hand threads are less common and are used in specific applications where a right-hand thread would be unsuitable, such as in CNC bridge saw machines. If you hold a left-hand threaded bolt or screw and turn it clockwise, it will move towards you. This is often remembered as “lefty-loosey,” as turning the screw to the left (clockwise) loosens it.

Identifying Thread Direction

Here’s a step-by-step guide on how to identify the thread direction of any screw, bolt, or nut:

- Visual Inspection: The easiest way to determine the thread direction is by visually inspecting the threads. If the threads angle up to the right, it’s a right-hand thread. If they angle up to the left, it’s a left-hand thread.

- Use the “Righty-Tighty, Lefty-Loosey” Rule: Try to turn the screw or bolt in a clockwise direction. If it moves away from you, it’s a right-hand thread. If it moves towards you, it’s a left-hand thread.

- Check the End of the Bolt or Screw: Some manufacturers mark the end of left-hand threaded bolts and screws with a groove or the letter ‘L’.

- Use a Thread Gauge: A thread gauge is a tool used to measure the pitch or lead of a screw thread. It can also help determine the thread direction.

Thread Direction in CNC Bridge Saws

In the stone industry, CNC bridge saws, like those from Donatoni or Noat, often use left-hand threads because the spindle used for CNC tools is the same one where the blade is installed. In this case, the head of the bridge saw will be tilted and the tools installed in the blade arbor.

Sometimes, some CNC bridge saws use a separate spindle for CNC operations, so in this case, the thread will be a standard right-hand

Conclusion

Identifying thread direction is a crucial skill for any professional in the CNC industry. With this knowledge, you can ensure that you’re using your CNC machines and other equipment correctly and safely. Remember, the right tools make all the difference in the quality of your work.

At our store, we offer a wide range of tools and adapters for CNC machines specifically designed for the stone industry. Each product listing includes detailed information about the thread direction to help you make the right choice for your needs.

Diamond Blades

Diamond Blades Angle Grinder Tools

Angle Grinder Tools Polishing Machine Tools for Stone, Marble and Granite

Polishing Machine Tools for Stone, Marble and Granite Texture tooling

Texture tooling Adhesives and glue

Adhesives and glue Ceramic, Granite and Marble Drill Bits

Ceramic, Granite and Marble Drill Bits Sculpture – Stone carving tools

Sculpture – Stone carving tools Diamond Wires for Granite and Marble Quarries

Diamond Wires for Granite and Marble Quarries Cemetery and Graveyard Accessories

Cemetery and Graveyard Accessories CNC Vacuum Pods

CNC Vacuum Pods CNC Tool Holders

CNC Tool Holders CNC Tool Forks

CNC Tool Forks Positioning Alignment Lasers

Positioning Alignment Lasers Material Handling

Material Handling Machinery

Machinery Spare parts

Spare parts Electrical Spare Parts

Electrical Spare Parts Personal Protective Equipment

Personal Protective Equipment