What is natural quartzite?

Natural quartzite is a metamorphic rock composed mainly of quartz. It is a rock formed by the transformation of sandstone (a sedimentary rock composed of sand grains) under the effect of high levels of pressure and temperature over millions of years. During this metamorphic process, the quartz grains in the sandstone compact and fuse together, creating a very hard and compact structure.

Natural quartzite has a range of colors that can vary from pure white to shades of gray, beige, brown, and even pink. It can also have layers or veins of other minerals that formed during the metamorphic process. Its surface is generally very smooth and can have a glassy appearance.

This stone is valued in the construction and architecture industry for its strength and durability. It is widely used for flooring, wall cladding, kitchen and bathroom countertops, stairs, and other applications where a durable and high-quality stone is required. Natural quartzite also requires proper maintenance to preserve its appearance and strength over time.

Examples of natural quartzite applications

Stone masons use quartzite to create a wide range of products and architectural elements. Here are some examples of common quartzite applications in the construction and architecture industry:

- Flooring: Quartzite is used for indoor and outdoor flooring. Stone masons cut quartzite into slabs or tiles of various sizes and lay them to create durable, long-lasting, and visually striking floors.

- Wall cladding: Quartzite can be used to cover walls and vertical surfaces. Stone masons create quartzite panels that are applied to walls to create an elegant and sophisticated look.

- Kitchen and bathroom countertops: Quartzite is very popular for making countertops, worktops, and bathroom sinks. Stone masons cut and shape quartzite to create surfaces that are resistant to heat, stains, and wear, adding a touch of luxury and style to the environment.

- Stairs: Quartzite can be used to cover stairs, creating elegant and durable steps. Stone masons can create custom quartzite steps, giving indoor and outdoor spaces a sophisticated look.

- Fireplaces: Quartzite is a popular choice for building fireplaces and fireplace cladding. Its heat resistance and natural beauty make it ideal for creating an eye-catching focal point in living areas.

- Decorative elements: Stone masons can use quartzite to create decorative elements such as columns, pedestals, frames, and other architectural sculptures. Quartzite can be shaped and worked to create custom elements that add distinctive details to spaces.

Most popular natural quartzites

Today, quartzites are widely recognized for their beauty, durability, and variety of colors. Here are five of the most commonly used:

- Taj Mahal quartzite: This precious quartzite comes from Brazil and is widely appreciated for its beauty and neutral tones. It has a white-cream color with light gray and gold veins. Its elegance and resistance make it a popular choice for flooring, wall cladding, and kitchen and bathroom countertops.

- Calacatta quartzite: This luxury quartzite has a similar appearance to Calacatta marble but offers greater durability due to its quartzitic nature. Originating from Brazil, it has a white base with large gray and gold veins. It is highly appreciated for its refined character and used in high-end design projects.

- Fantasy Brown quartzite: Also known as Brown Antique, this quartzite comes from India. It has a unique color combination, with shades of brown, gray, white, and cream. Its veins and shades offer a distinctive and rich look. It is often used for wall cladding, flooring, and kitchen countertops.

- White Macaubas quartzite: Originating from Brazil, this quartzite has a pure white color with gray veins and shades of blue. Its elegant and luminous appearance makes it a popular choice for applications where a modern and minimalist design is desired. It is often used for cladding, flooring, and kitchen countertops.

- Mont Blanc quartzite: This quartzite comes from Brazil and is known for its appearance similar to Carrara white marble. It has a white base with gray veins and a delicate pattern. Its combination of elegance and durability makes it suitable for a variety of applications, including flooring, cladding, and kitchen and bathroom countertops.

Physical Characteristics of Quartzite (Why it’s Difficult to Work With)

Natural quartzite is characterized by being exceptionally hard and at the same time fragile.

Main characteristics:

- Hardness: Quartzite is extremely hard and compact due to its high quartz content. It has a level 7 on the Mohs scale. Its hardness can vary, but in general, it is harder than marble and even common granites. This characteristic makes it more difficult to cut, shape, or polish compared to other stones.

- Fragility: Despite its hardness, natural quartzite can be relatively fragile. It can be subject to fractures or breaks if not handled carefully during the processing. This requires greater attention and precision during cutting and shaping operations.

- Presence of accessory minerals: Quartzite may contain traces of accessory minerals that make the material more difficult to work with. For example, the presence of minerals such as mica or graphite can affect the strength of quartzite and cause problems during the processing.

- Abrasiveness: Quartzite can be abrasive, which means that it can quickly wear down the tools and blades used to work with it. This requires the use of high-quality tools and materials, often with diamond inserts, to ensure an effective and long-lasting result.

- Low porosity: Natural quartzite has low porosity, which means it absorbs less water than other stones. However, this characteristic can make it more difficult for adhesives or fillers to adhere during fixing or repair operations.

For this reason, it is advisable to rely on experienced professionals for the processing of natural quartzite and to use specific and high-quality tools to achieve optimal results.

Specific Tools for Natural Quartzite

When working with natural quartzite, it is important to use specific tools that are designed for this hard and dense material. Always work with wet tools and expect a higher tool consumption compared to working with softer materials.

Diamond Blades

Diamond Blades Angle Grinder Tools

Angle Grinder Tools Polishing Machine Tools for Stone, Marble and Granite

Polishing Machine Tools for Stone, Marble and Granite Texture tooling

Texture tooling Adhesives and glue

Adhesives and glue Ceramic, Granite and Marble Drill Bits

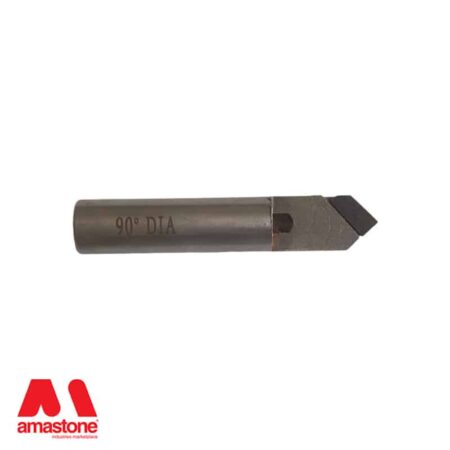

Ceramic, Granite and Marble Drill Bits Sculpture – Stone carving tools

Sculpture – Stone carving tools Diamond Wires for Granite and Marble Quarries

Diamond Wires for Granite and Marble Quarries Cemetery and Graveyard Accessories

Cemetery and Graveyard Accessories CNC Vacuum Pods

CNC Vacuum Pods CNC Tool Holders

CNC Tool Holders CNC Tool Forks

CNC Tool Forks Positioning Alignment Lasers

Positioning Alignment Lasers Material Handling

Material Handling Machinery

Machinery Spare parts

Spare parts Electrical Spare Parts

Electrical Spare Parts Personal Protective Equipment

Personal Protective Equipment