La società MMG SERVICE SRL ha ricevuto nel corso del 2020 e 2021 gli aiuti di stato pubblicati sul RNA sezione Trasparenza.

CNC Stubbing Wheels

Showing all 19 results

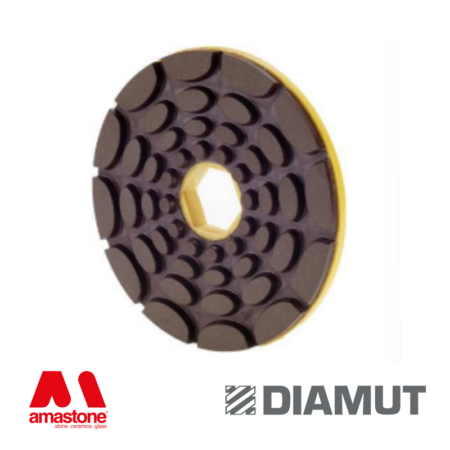

CNC Vacuum-brazed universal-use stubbing wheel – Amastone

Electroplated cutting tool for sinks | radiused Ø85 – Marble

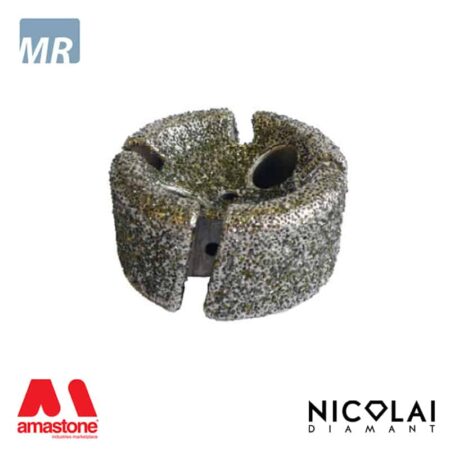

CNC Stubbing Wheels for Natural Quartzite – Nicolai

Stubbing wheel for granite – Amastone

1/2 gas – M14 Granite Stubbing Wheel

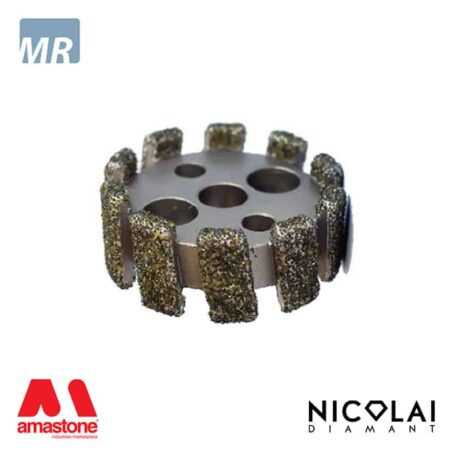

Segmented ball head mill – Nicolai

Electroplated ball head mill – Nicolai

CNC Stubbing Wheels for Granite and Marble

Diamond stubbing wheels (also known as gauging wheels or calibration wheels) are used for surface milling, material removal (recessing and pocketing), and calibration with numerical controlled machined tools and 5-axis machines and robots on marble, granite, and engineered stone. There are many types and models of stubbing wheels to choose from.

Stubbing wheel fittings are usually flanged but 1/2-gas connections are also available for use on routing machines and for light removal.

A cone with this type of fitting or a 1/2″ gas-flange adaptor is needed for stubbing wheels having flanged connections.

The various versions of the stubbing wheels also differ based on diameter and useful cutting height.

How to choose the correct stubbing wheel?

This depends on the material to be worked, the machine, and the application.

- As with the other tool categories, the following rules hold true:

Sintered wheels are used to work granite and engineered stone;

Electroplate wheels are used for working marble and stone. - If you can’t use a flanged fitting, a wheel with a 1/2 gas connection is needed.

- For light removal, small-diameter stubbing wheels or those with a half- gas connection can be used.

- If you use the stubbing wheel on 5-axis CNC 5 machines or Robots, we suggest the concave stubbing wheels.

- For heavy-duty material removal on granite or a high-power CNC machine, the Turbo Granite scrubbing wheels is the tool to use.

General advice on using stubbing wheels:

Stubbing wheels are very large-diameter tools (compared with finger bits or core drill bits) and for this reason, we recommend you use a plunge depth proportional to the spindle power. The plunge depth may vary from 0.5 mm for a machine with a very small spindle, such as for example a 2.2 or a 3.7Kw spindle, or up to a 5-mm plunge depth for an 11 or 15 kW electric spindle. If your CNC machine spindle is not powerful enough, we recommend a version with a half-gas connection or at least one with a small diameter.

Related CNC Stone Tools categories:

- CNC Finger Bits (cutting, profiling, milling, sink cut-out)

- CNC Drill Bits (drilling)

- CNC Engraving Bits (engraving, writing, finishing, and super-finishing)

- CNC Carving tools (roughing, V-Carve roughing, V-Carving)

- CNC Profiling and Profile Wheels (edge profiling and polishing)

- CNC Drain Board Tools (grooving)

- CNC Machine blades

- Polycrystalline bits

- CNC Replacement Head Bits

For any information on these wheels, please don’t hesitate to contact us at

Diamond Blades

Diamond Blades Angle Grinder Tools

Angle Grinder Tools Polishing Machine Tools for Stone, Marble and Granite

Polishing Machine Tools for Stone, Marble and Granite Texture tooling

Texture tooling Adhesives and glue

Adhesives and glue Ceramic, Granite and Marble Drill Bits

Ceramic, Granite and Marble Drill Bits Sculpture – Stone carving tools

Sculpture – Stone carving tools Diamond Wires for Granite and Marble Quarries

Diamond Wires for Granite and Marble Quarries Cemetery and Graveyard Accessories

Cemetery and Graveyard Accessories CNC Vacuum Pods

CNC Vacuum Pods CNC Tool Holders

CNC Tool Holders CNC Tool Forks

CNC Tool Forks Positioning Alignment Lasers

Positioning Alignment Lasers Material Handling

Material Handling Machinery

Machinery Spare parts

Spare parts Electrical Spare Parts

Electrical Spare Parts Personal Protective Equipment

Personal Protective Equipment