Electroplated tools are of fundamental importance for any CNC machinist who wants to work on marble or stone. These tools consist of a steel core covered with abrasive diamond grains bonded to the metal surface via the electroplating process.

The most popular electroplated tools are: 10mm shank flat head finger bits, 10mm shank round head finger bits, stubbing wheels.

Electroplated tools for marble

Diverse methods exist to work marble or stone using electroplated tools but in all cases, the tool’s useful life and performance must be considered. An improperly used tool may result in wasted time and money. The steel core of the electroplated tool can be used only for as long as it is covered with abrasive diamonds.

Electroplated tools are often misused

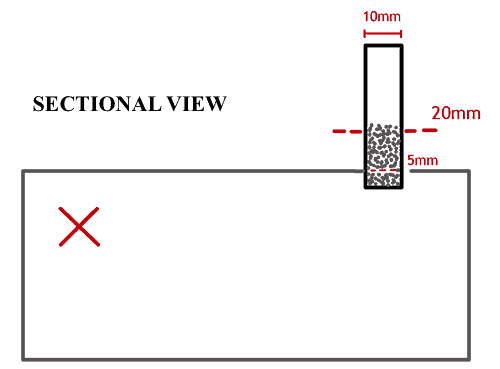

Marble machinists often misuse tools. One common error consists of only partially using the tool. For example, a marble worker might make a cut using just the bottom 4 or 5 mm of a tool with a 20-mm cutting surface. Why might he do this? Out fear of breaking the tool shaft or overstaining the machine. This will result in the bottom of the tool wearing down while the top of the bit is still unused. What a waste! This is certainly not the best approach!

What is the right way to use diamond tools?

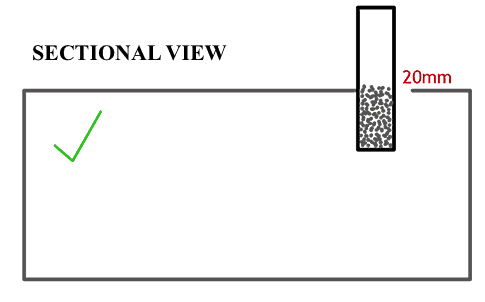

The basic rule to properly use an electroplated diamond tool is to use the entire available height of the cutting surface. This will ensure it wears out evenly.

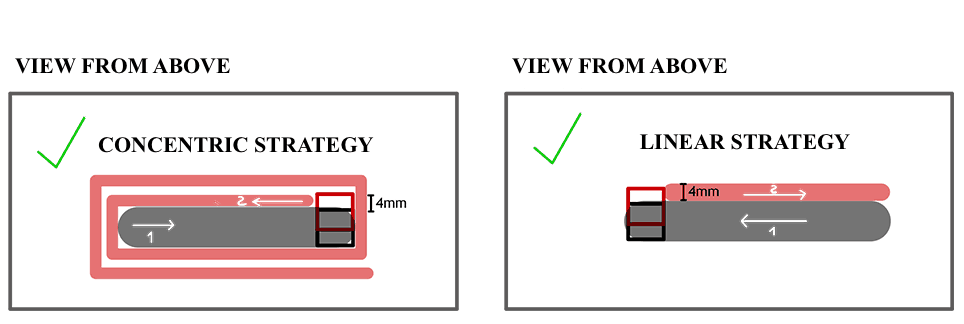

If a given CNC machine has insufficient power, (perhaps due to an overstrained electrospindle or a weak machine structure), one solution is to cut with just a portion of the tool diameter but employing the entire height of the cutting surface. In this case, the width of cut must be smaller than the tool diameter. For example, using an X-Y step equal to 20% of the tool diameter. This will lower the stress on the electrospindle and the entire machine, in general. More importantly, the tool will be consumed evenly, increasing yield considerably in terms of linear meters that can be worked.

The first drawing below illustrates how NOT to use electroplated diamond tools whereas the second drawing shows the correct use, employing the diamond tool’s full cutting height and cutting deep into the material.

Solution by changing the feed rate and the pitch

Generally, whether working with a linear or spiral roughing strategy, the width of the first tool path generated by the CAD / CAM software will correspond to the entire tool diameter, and after that, the tool paths generated will be offset by the selected step. This means you will need to manually lower the feed rate for the first pass and raise back 100% for the second and subsequent passes.

Manually varying the feed speed based on the width of cut is an impractical solution for a piece that needs to be rough cut at several different points. But we have a solution to that problem too!

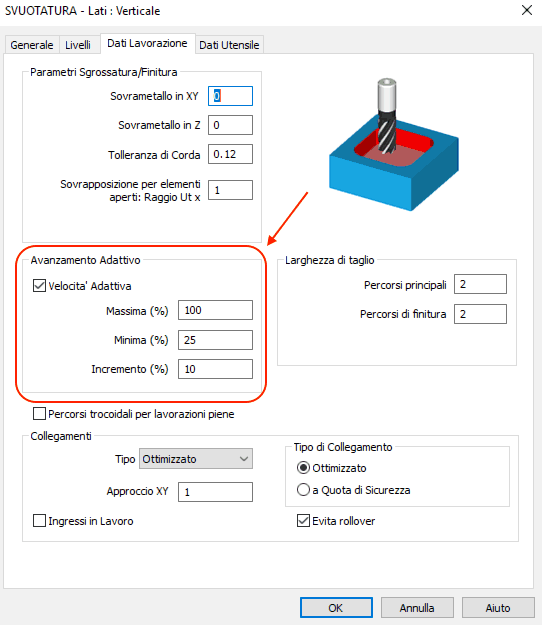

The Adaptive Feed solution in advanced CAD/CAM software

Advanced CAT/CAM software, such as Alphacam (compatible with our “Next” 3 axis CNC stone router) solves this problem automatically with its Adaptive Feed function (other CAD/CAM software packages have similar solutions for this problem). Using this function, you effectively tell the machine to work at a feed speed inversely proportional to the quantity of material to be removed.

Processing times can be halved with Adaptive Feed without overstraining the machine or compromising safety. This is because the feed speed will increases proportionally and automatically as the width of cut decreases with respect to the tool diameter and vice versa, the feed speed will decrease proportionally and automatically as the width cut of increases with respect to the tool diameter.

The image below shows a screenshot in the Italian version of Alphacam 2018 screenshot in which the adaptive speed parameters have been set. Of course, we offer the Alphacam software in English and all other available languages.

Diamond Blades

Diamond Blades Angle Grinder Tools

Angle Grinder Tools Polishing Machine Tools for Stone, Marble and Granite

Polishing Machine Tools for Stone, Marble and Granite Texture tooling

Texture tooling Adhesives and glue

Adhesives and glue Ceramic, Granite and Marble Drill Bits

Ceramic, Granite and Marble Drill Bits Sculpture – Stone carving tools

Sculpture – Stone carving tools Diamond Wires for Granite and Marble Quarries

Diamond Wires for Granite and Marble Quarries Cemetery and Graveyard Accessories

Cemetery and Graveyard Accessories CNC Vacuum Pods

CNC Vacuum Pods CNC Tool Holders

CNC Tool Holders CNC Tool Forks

CNC Tool Forks Positioning Alignment Lasers

Positioning Alignment Lasers Material Handling

Material Handling Machinery

Machinery Spare parts

Spare parts Electrical Spare Parts

Electrical Spare Parts Personal Protective Equipment

Personal Protective Equipment