(…and Why our Vacuum pods are chosen by the best CNC manufacturers for stone and glass working)

The CNC Vacuum Pods provide the safest holding system for stone and glass CNC machines.

If they don’t use Vacuum Pods stone fabricators often have to drill into a marble slab or need to work around the edges of a granite countertop. The slab must be raised from the top of the table and properly held so as not to move during machining. With aCNC Vacuum Pods’ System, this kind of job is safer and faster than using brackets or other improvised clamping systems.

Every innovative system encounters a few problems in the beginning. Thanks to their extensive experience, research, and continual development through their collaboration with the best CNC machine makers, GNC Meccanica now have a solution for each of these problems.

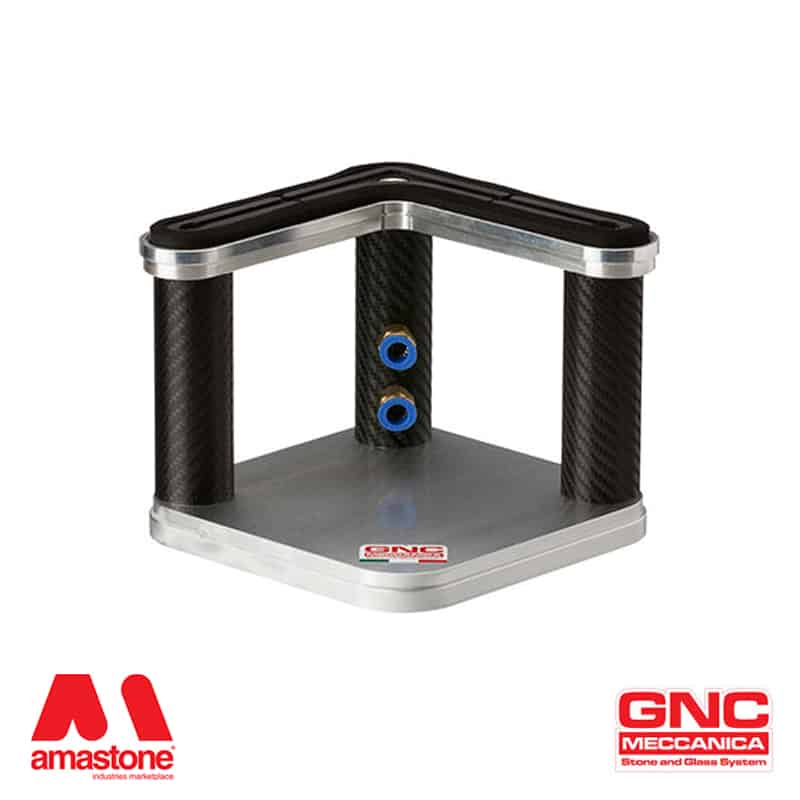

CNC Vacuum Pods are available as in different sizes and shapes: Round, Square, Rectangular and Corner pods.

A SOLUTION FOR ANY PROBLEM

Do your CNC Vacuum Pods stain your workpieces or even scratch them?

With our CNC Vacuum Pods you won’t have any problems with rubber marks because we use only stain-resistant rubber for both the top and the seals. You don’t need to worry about scratches! Thanks to the vulcanized rubber in the plate the workpieces come into contact only with the delicate rubber, eliminating the risk of scratches.

Do you have different heights also in the same model of CNC Vacuum Pods

Our CNC Vacuum Pods are all certified to a tolerance of +/- 0.02 mm before being shipped.

Are you sure that your current suction cups are able to comply with this measure? Many companies do not even verify their suction cups before sending them.

Does the rubber top detach or delaminate in your CNC Vacuum Pods?

All rubber tops on our CNC Vacuum Pods are hot-vulcanized directly on aluminium, allowing us to guarantee our product against detachment and delamination during its lifetime.

Would you be able to replace a foam gasket with rubber lips and vice versa in the same Suction Pod?

Many customers ask for a rubber lip to work their “shiny” pieces while others ask for a foam gasket to work raw or even resin pieces.

That’s why we’ve created and developed a suction plate that can accommodate both the rubber lip and mousse seal. You simply remove one and replace with the other, without needing to use glues or any other substance.

CNC VACUUM PODS MODEL SELECTION AND CUSTOMIZING TO YOUR NEEDS

We supply a lot of different versions of CNC Vacuum Pods on amastone.com. To make your selection you must choose one with all the right features for you.

(On every product page throughout our website you’ll find a configurator that will help you to select the right CNC Vacuum Pods for your needs)

- The geometric shape of the pads: you can choose between square, rectangular, round and corner cups.

- The height of the vacuum pod: it is possible to choose heights from 30 mm up to 240 mm.

- Make of machine: if you already have suction cups in your machine, you can get more CNC Vacuum Pods of the same height so you can use them with the ones you already have.

- Single effect model: the cup has the vacuum only in the top base (in the surface) and it’s fixed to the worktable mechanically.

- Double effect model: the cup has the vacuum either in the top base surface (to hold the slab to be machined) or in the bottom base (to secure the suction cup to the machine’s working table).

- Top surface: suction cups with the rubber lip or the mousse on the top surface. The mousse adapts better to the surface of the material and is therefore recommended for machining materials with irregular surfaces such as stone.

- Base surface: in the case of the double effect model, it’s possible to choose the base surface with OR rubber or EPDM rubber for a maximum grip.

- Air fitting: it’s possible to select the size of the air fitting from 6 up to 12 mm.

Diamond Blades

Diamond Blades Angle Grinder Tools

Angle Grinder Tools Polishing Machine Tools for Stone, Marble and Granite

Polishing Machine Tools for Stone, Marble and Granite Texture tooling

Texture tooling Adhesives and glue

Adhesives and glue Ceramic, Granite and Marble Drill Bits

Ceramic, Granite and Marble Drill Bits Sculpture – Stone carving tools

Sculpture – Stone carving tools Diamond Wires for Granite and Marble Quarries

Diamond Wires for Granite and Marble Quarries Cemetery and Graveyard Accessories

Cemetery and Graveyard Accessories CNC Vacuum Pods

CNC Vacuum Pods CNC Tool Holders

CNC Tool Holders CNC Tool Forks

CNC Tool Forks Positioning Alignment Lasers

Positioning Alignment Lasers Material Handling

Material Handling Machinery

Machinery Spare parts

Spare parts Electrical Spare Parts

Electrical Spare Parts Personal Protective Equipment

Personal Protective Equipment