Pneumatic Pin-Stop Locator for CNC

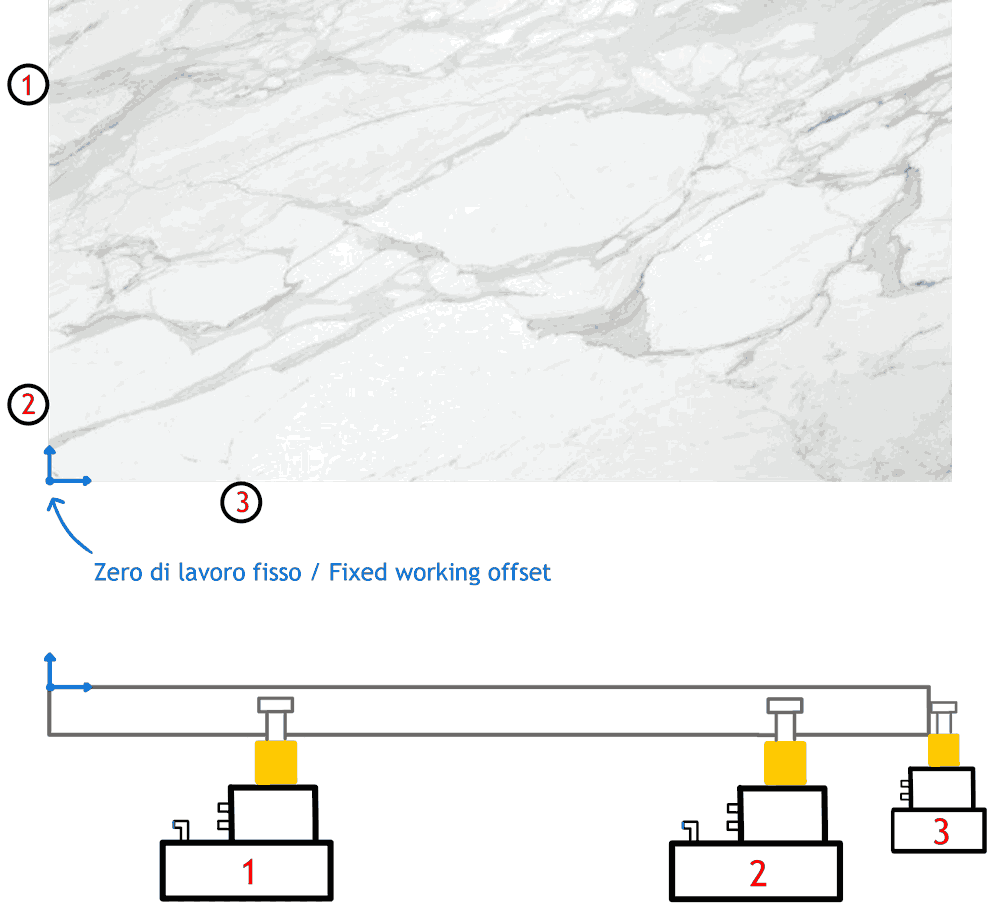

A Pneumatic Pin-Stop Locator, also known as a backstop, is a device that is used in CNC (computer numerical control) machines to help position and secure a workpiece during machining operations. It consists of a pneumatic pin that can be positioned and locked into place, acting as a stop to limit the travel of the workpiece.

The pneumatic pin-stop locator is typically mounted on the machine’s table or workholding fixture, and the workpiece is positioned against the pins to create a reference point. Once the pins are in the correct position, they can be locked in place with the use of air pressure, securing the workpiece in position. This enables the machine to perform precise cuts and operations on the workpiece.

The backstop can also be programmed to move and change position depending on the needs of the workpiece and the desired operation. This makes it a versatile and efficient device for positioning and holding workpiece during CNC machining. This can be a cost-efficient solution for the CNC machines to prevent the need for purchasing specialized jigs and fixtures which can be expensive.

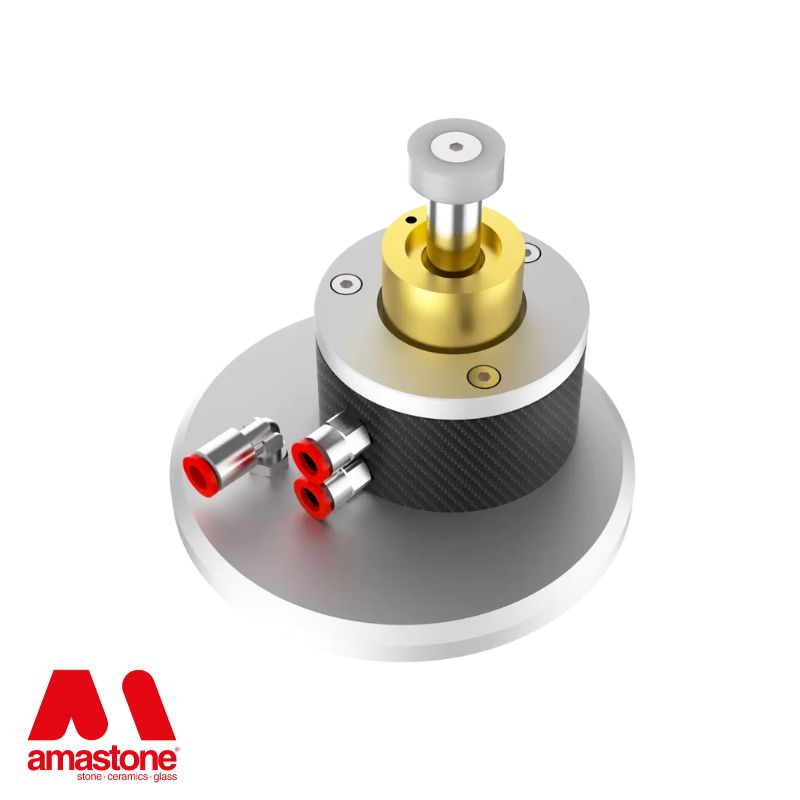

These pneumatic locating device are composed of a vacuum base, a body frame made of anodized aluminum, a rectified Pneumatic Brass cylinder, a stainless steel piston, striking pin made of plastic, and Viton seals for durability. An aluminum support locking and bottom seal silicone 50SH to guarantee a secure hold of workpiece.

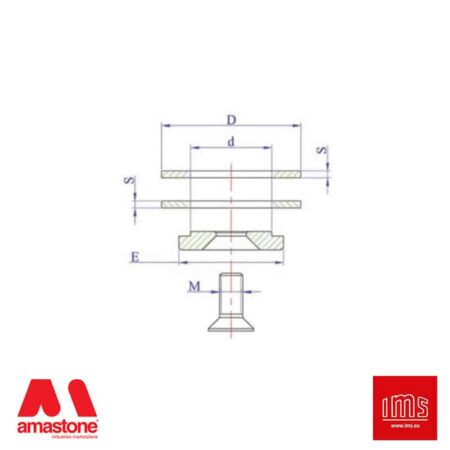

These pin-stop locators are usually available in stock, ready to dispatch, with the following three heights:

- 100 mm

- 105 mm (specifically designed for Omag, Intermac, Northwood CNC machines)

- 120 mm (specifically designed for Denver, Donatoni CNC machines).

You can also order pin-stop locators with different heights, but please be aware that the production time for these orders can take around 20/30 days.

Diamond Blades

Diamond Blades Angle Grinder Tools

Angle Grinder Tools Polishing Machine Tools for Stone, Marble and Granite

Polishing Machine Tools for Stone, Marble and Granite Texture tooling

Texture tooling Adhesives and glue

Adhesives and glue Ceramic, Granite and Marble Drill Bits

Ceramic, Granite and Marble Drill Bits Sculpture – Stone carving tools

Sculpture – Stone carving tools Diamond Wires for Granite and Marble Quarries

Diamond Wires for Granite and Marble Quarries Cemetery and Graveyard Accessories

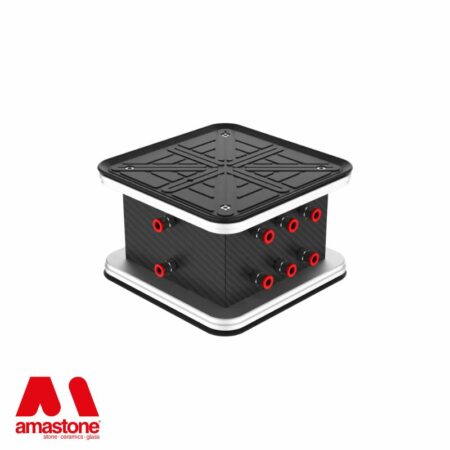

Cemetery and Graveyard Accessories CNC Vacuum Pods

CNC Vacuum Pods CNC Tool Holders

CNC Tool Holders CNC Tool Forks

CNC Tool Forks Positioning Alignment Lasers

Positioning Alignment Lasers Material Handling

Material Handling Machinery

Machinery Spare parts

Spare parts Electrical Spare Parts

Electrical Spare Parts Personal Protective Equipment

Personal Protective Equipment

Reviews

There are no reviews yet.