La società MMG SERVICE SRL ha ricevuto nel corso del 2020 e 2021 gli aiuti di stato pubblicati sul RNA sezione Trasparenza.

Granite Cutting Tools and Granite Tooling

Showing 1–60 of 159 results

Polycrystalline PCD Router Bit for granite – Amastone

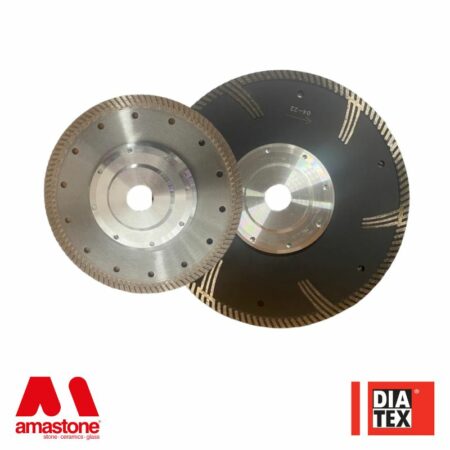

Angle grinder blade for granite – Diatex

Cutting blade with turbo crown for reinforced concrete – Sankyo RD

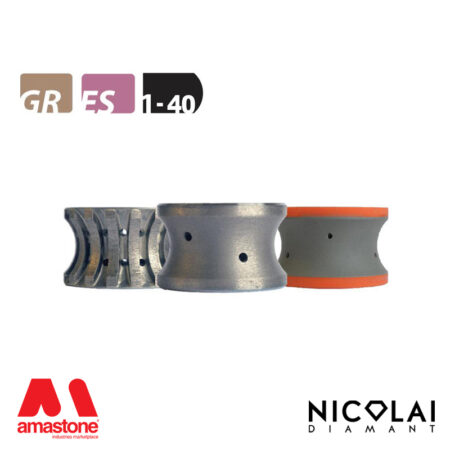

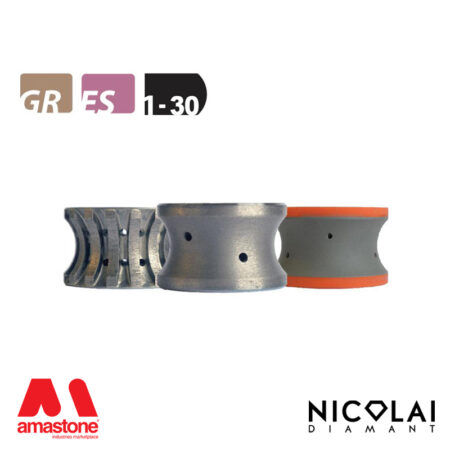

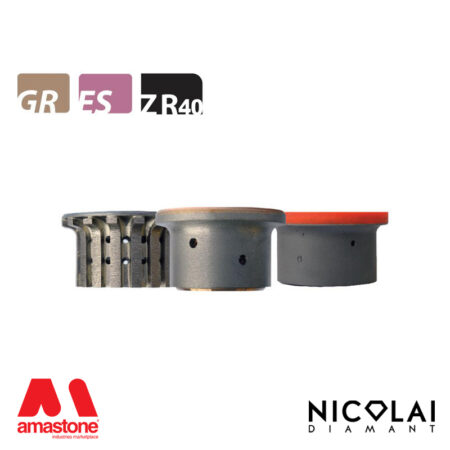

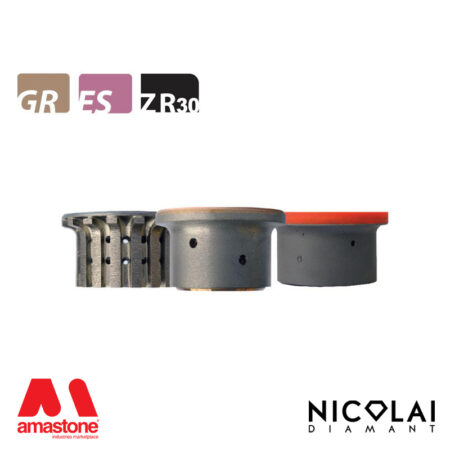

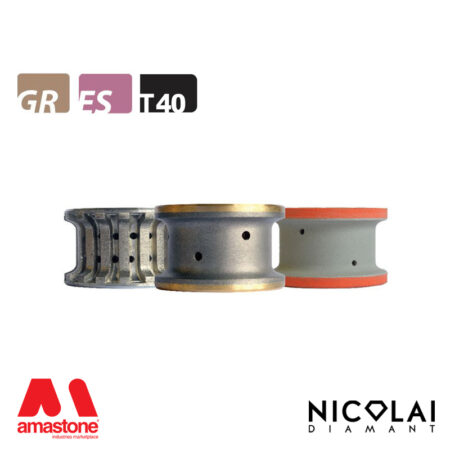

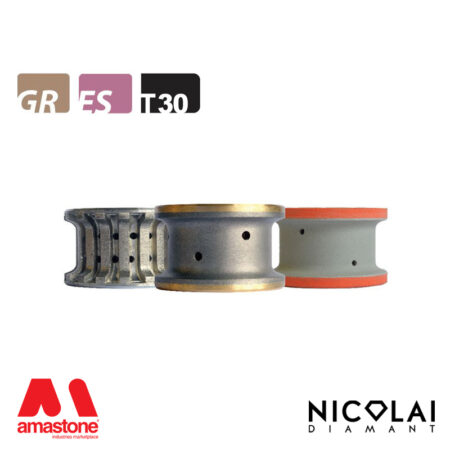

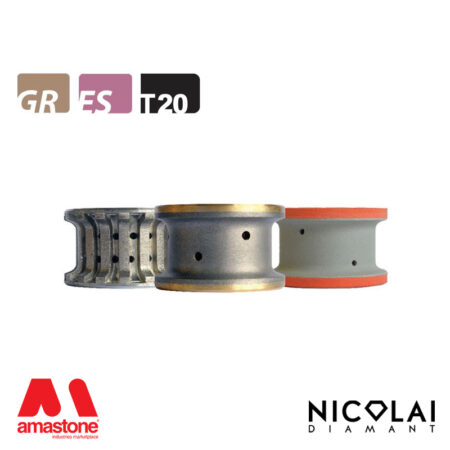

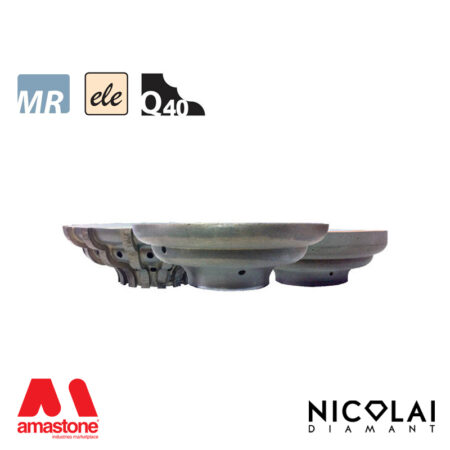

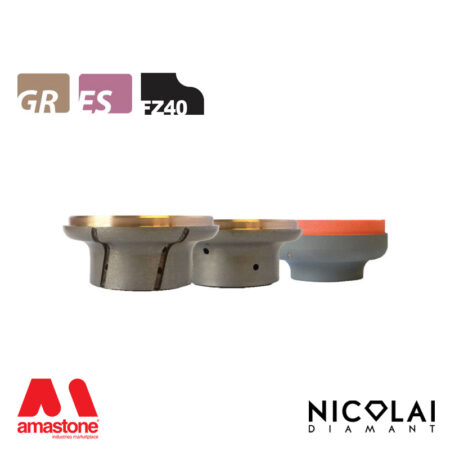

Segmented calibrating wheel for kitchen top edge “Super Z” – Nicolai

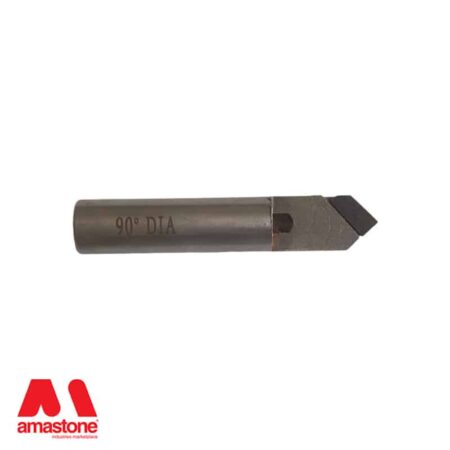

Carbide V-Groove Router Bits

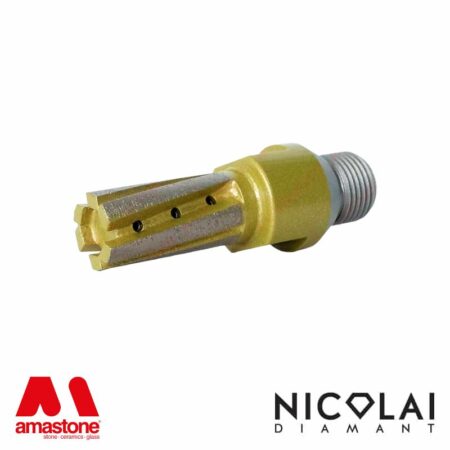

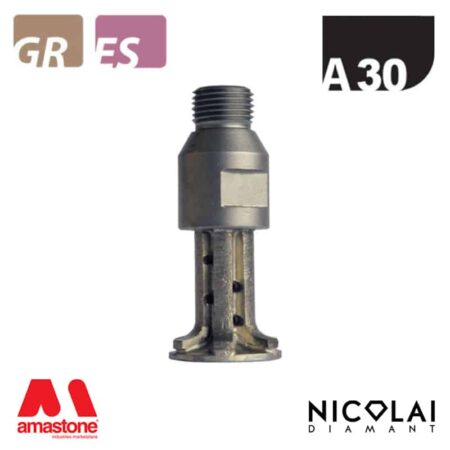

Conical router bit for Granite – Nicolai

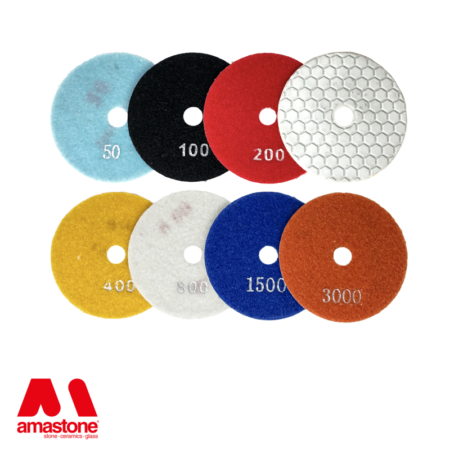

Wet polishing pads “Nippon 3” for engineered stone Ø100 mm – Amastone

DIAFACE Wet Polishing Pads Ø100 mm – SORMA

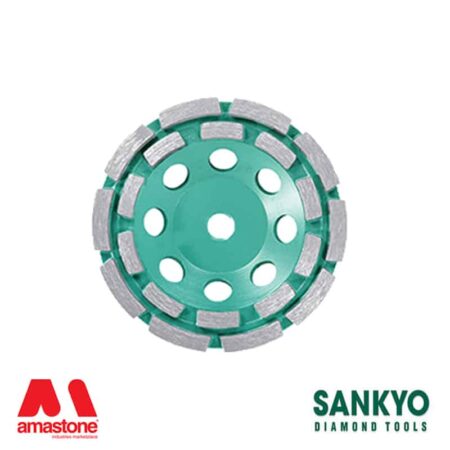

Diamond grinding wheel with double row segment for marble “SD-PCE” – Sankyo

Diamond cup wheel for marble “SD-PC” – Sifa

Diamond cup wheel for granite “SD-PW” – Sifa

Cutting blade with turbo crown for engineered stone – Sankyo Razor

Cutting blade with turbo crown for granite – Sankyo RS

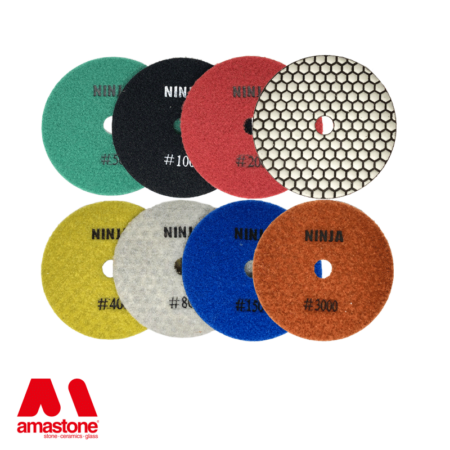

NINJA Dry polishing pads

Electroplated diamond carving tool for ceramic and granite – Diamar

Electroplated anchor bits type Fischer – Diamar

Granite Abrasive semi-rigid Discs on fibre – SAITRON Sait

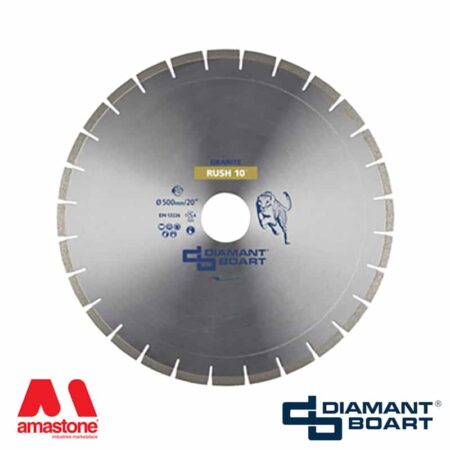

Granite Bridge Saw Blades “Rush B” – Diamant Boart

Granite Bridge Saw Blades “Rush DTA” – Diamant Boart

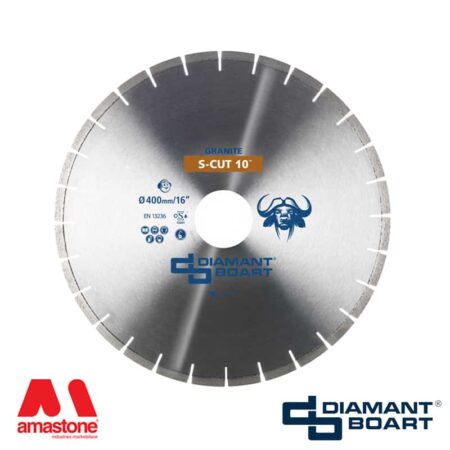

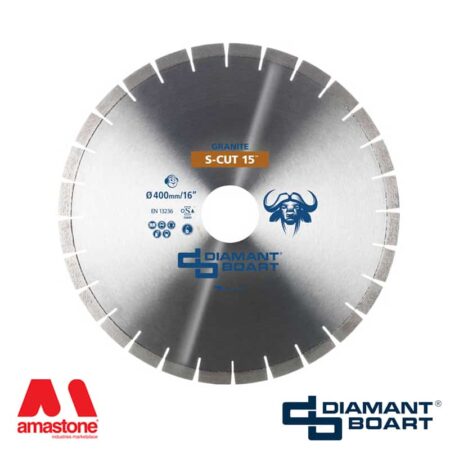

Granite Bridge Saw Blades “S-Cut” – Diamant Boart

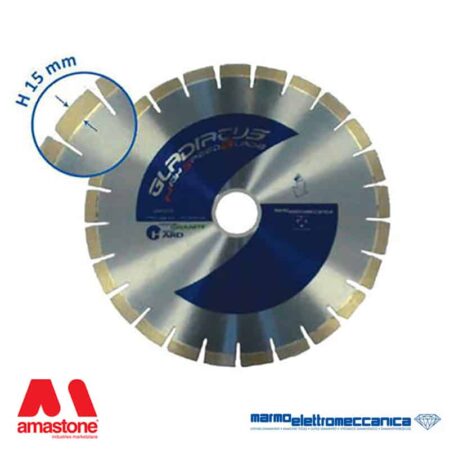

Granite Bridge Saw Blades – MarmoElettromeccanica

Segmented ball head mill – Nicolai

Granite Cutting and Polishing Tools

Granite Fabrication Tooling and Equipment

Granite is a very hard natural rock material used to make countertops, monuments, floor tiles, and many other products. Granite is hard enough to resist abrasion, inert enough to resist weathering, and it’s possible to work it to obtain a brilliant polished material.

Because of its characteristics, granite is also hard to work so stone fabricators use special granite tools to cut, shape, engrave, drill, polish, and so on.

We have tagged all granite tools available to have them on a single category page. Granite tools include CNC granite finger bits, granite stubbing wheels, V-bits, and granite polishing pads.

Choose the right granite tool for your application and if you need assistance contact us: at

We have power tools granite tools and also CNC Granite tools.

Best-selling CNC granite tools:

- Yellow Z5 finger bit – Granite – Nicolai

- Stubbing wheel for heavy removal – Diamut

- High-speed finger bit Black Storm – Granite, Engineered Stone – Diamut

Granite working stages:

Granite cutting, polishing, and grinding are essential stages in the process of transforming a raw granite slab into a finished product, such as a countertop, flooring tile, or decorative item.

Cutting and shaping granite slabs: This stage involves using specialized tools, such as diamond saw blades, CNC finger bits, or diamond wires, to slice the granite slab into desired sizes and shapes. The precision of the cuts is crucial to ensure that the final product fits the intended space and looks aesthetically pleasing. Using the best cutting tools is important to ensure clean cuts and minimize the wastage of the expensive granite slab.

Grinding: Grinding is a stage that is sometimes necessary to flatten or level the surface of the granite. It involves using specialized grinding machines with diamond abrasive discs to remove any unevenness or roughness on the surface. The grinding process can also be used to remove any stains or blemishes on the granite. High-quality grinding tools are necessary to achieve a precise and even result without damaging the granite surface.

Polishing: Once the granite is cut, it undergoes a polishing process to enhance its natural beauty and durability. Polishing involves using progressively finer grits of granite polishing pads to remove any scratches or marks left by the cutting process and create a smooth and shiny surface. High-quality polishing tools are essential to achieve a consistent and uniform finish without damaging the granite surface.

Using the best tools for each stage of the granite cutting, polishing, and grinding process is crucial to ensure that the final product meets the desired specifications and quality standards. High-quality tools not only produce better results but also increase efficiency and reduce the risk of damage to the expensive granite slab. Investing in the best tools is a worthwhile expense for professionals in the granite industry, as it can lead to higher customer satisfaction, repeat business, and a stronger reputation for quality stone fabricators.

Diamond Blades

Diamond Blades Angle Grinder Tools

Angle Grinder Tools Polishing Machine Tools for Stone, Marble and Granite

Polishing Machine Tools for Stone, Marble and Granite Texture tooling

Texture tooling Adhesives and glue

Adhesives and glue Ceramic, Granite and Marble Drill Bits

Ceramic, Granite and Marble Drill Bits Sculpture – Stone carving tools

Sculpture – Stone carving tools Diamond Wires for Granite and Marble Quarries

Diamond Wires for Granite and Marble Quarries Cemetery and Graveyard Accessories

Cemetery and Graveyard Accessories CNC Vacuum Pods

CNC Vacuum Pods CNC Tool Holders

CNC Tool Holders CNC Tool Forks

CNC Tool Forks Positioning Alignment Lasers

Positioning Alignment Lasers Material Handling

Material Handling Machinery

Machinery Spare parts

Spare parts Electrical Spare Parts

Electrical Spare Parts Personal Protective Equipment

Personal Protective Equipment